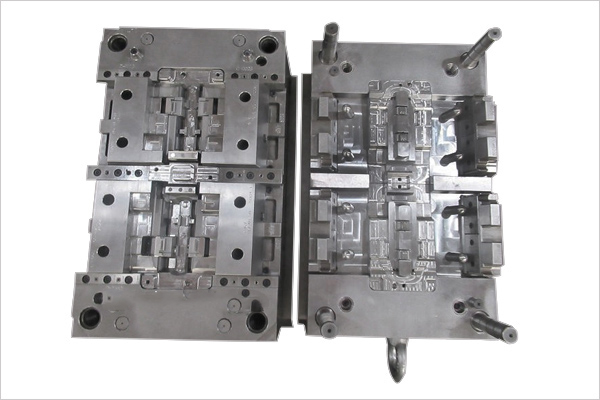

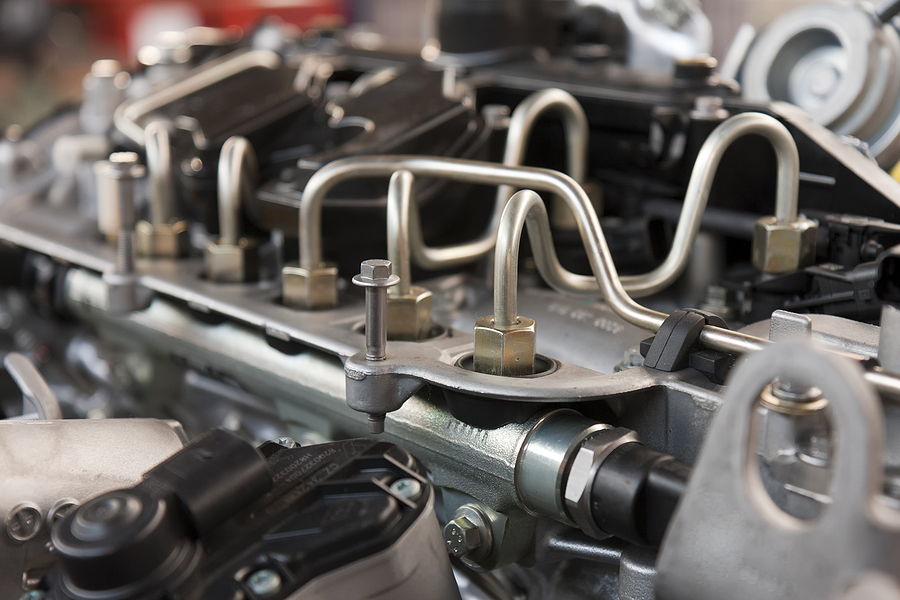

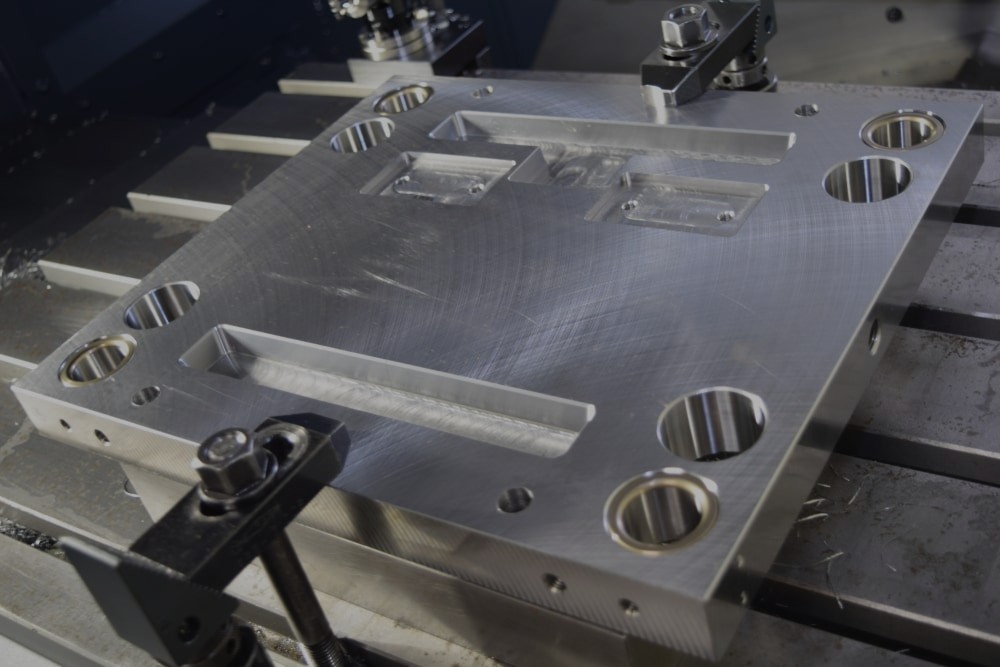

PVC Molds for Automotive Components

Polyvinyl chloride (PVC) is a versatile material widely used in the automotive industry, particularly for creating molds that produce high-quality components. Its unique combination of durability, flexibility, and cost-efficiency makes it an excellent choice for manufacturing a range of automotive parts, such as interior panels, seals, wiring insulation, and protective covers. One of the key […]

PVC Molds for Automotive Components Read More »