Overmolding in Automotive Manufacturing

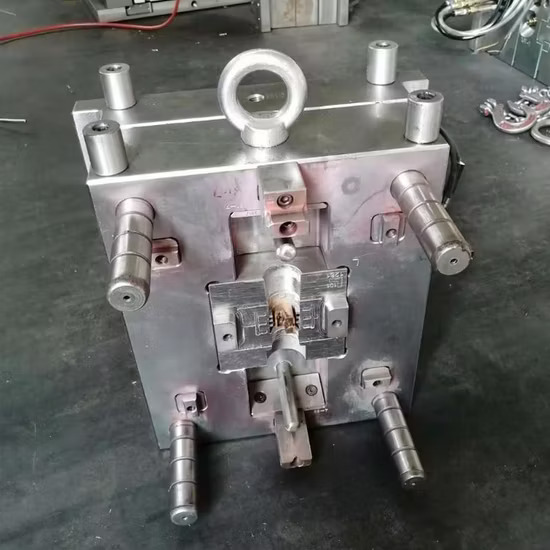

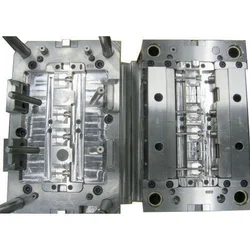

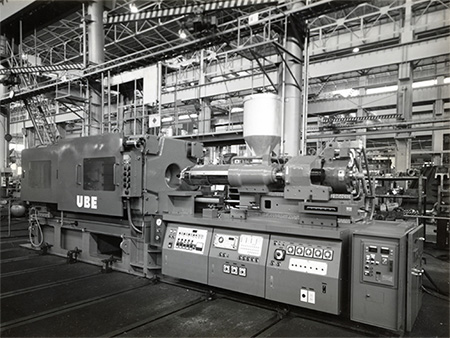

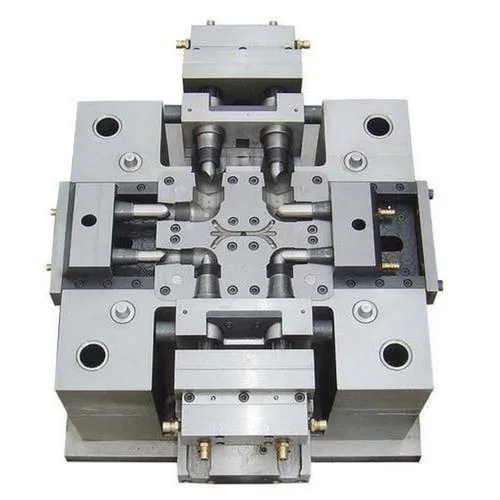

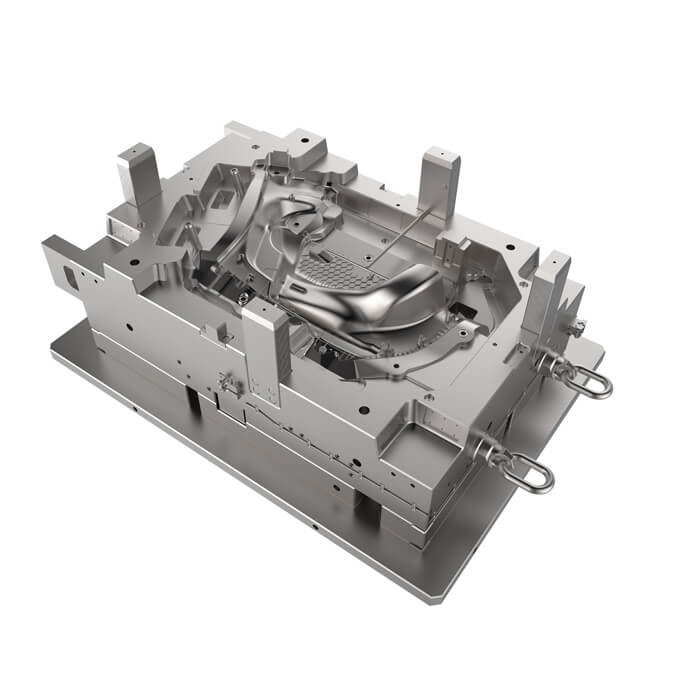

Overmolding is an advanced manufacturing process used in the automotive industry to enhance the functionality, durability, and aesthetics of components. It involves molding one material over another to create a single, cohesive part with multiple material properties. This technique has become increasingly prevalent due to its ability to streamline production, reduce assembly time, and improve […]

Overmolding in Automotive Manufacturing Read More »