Thermoplastics Materials Used in Injection Molding

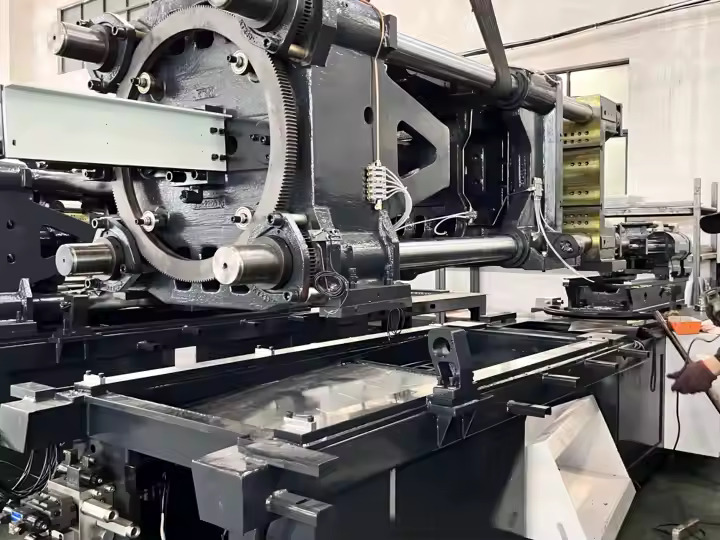

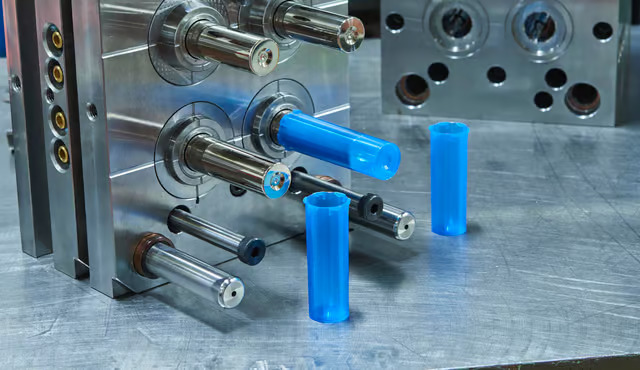

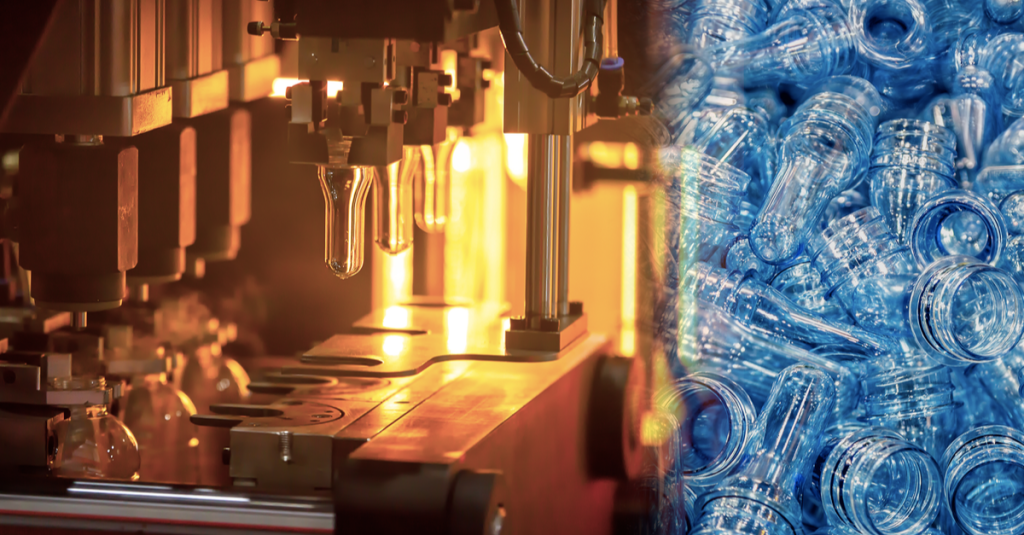

Thermoplastics are the backbone of injection molding, prized for their versatility, durability, and recyclability. These materials soften when heated and harden upon cooling, allowing for precise molding and reshaping. Commonly used thermoplastics in injection molding include polypropylene (PP), known for its lightweight and chemical resistance, making it ideal for automotive parts and packaging. Acrylonitrile Butadiene […]

Thermoplastics Materials Used in Injection Molding Read More »