Introduction to PVC Molds and their Applications

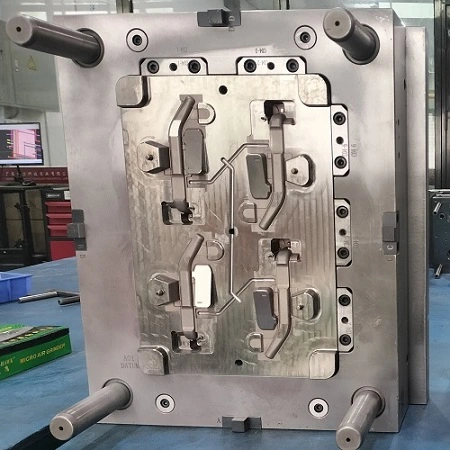

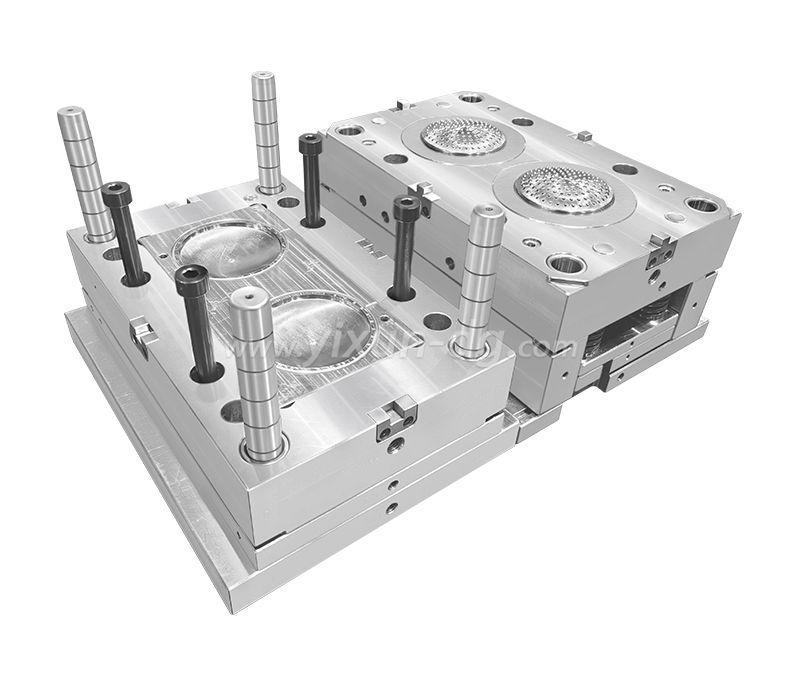

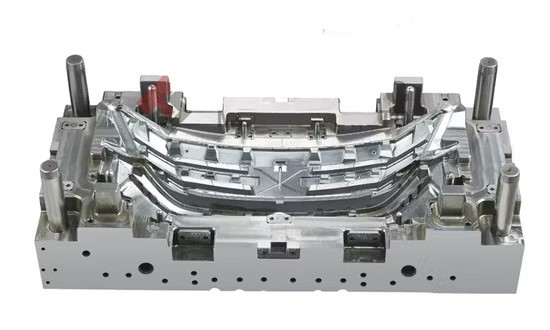

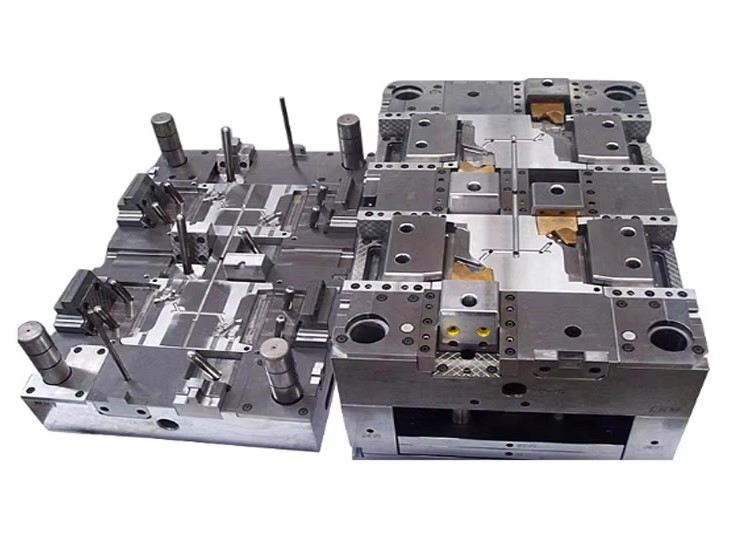

PVC (Polyvinyl Chloride) molds are essential tools in manufacturing products made from PVC, a versatile thermoplastic polymer widely used in various industries. PVC is valued for its durability, chemical resistance, and adaptability, making it suitable for diverse applications ranging from construction materials to consumer goods. PVC molds are designed to shape molten or softened PVC […]

Introduction to PVC Molds and their Applications Read More »