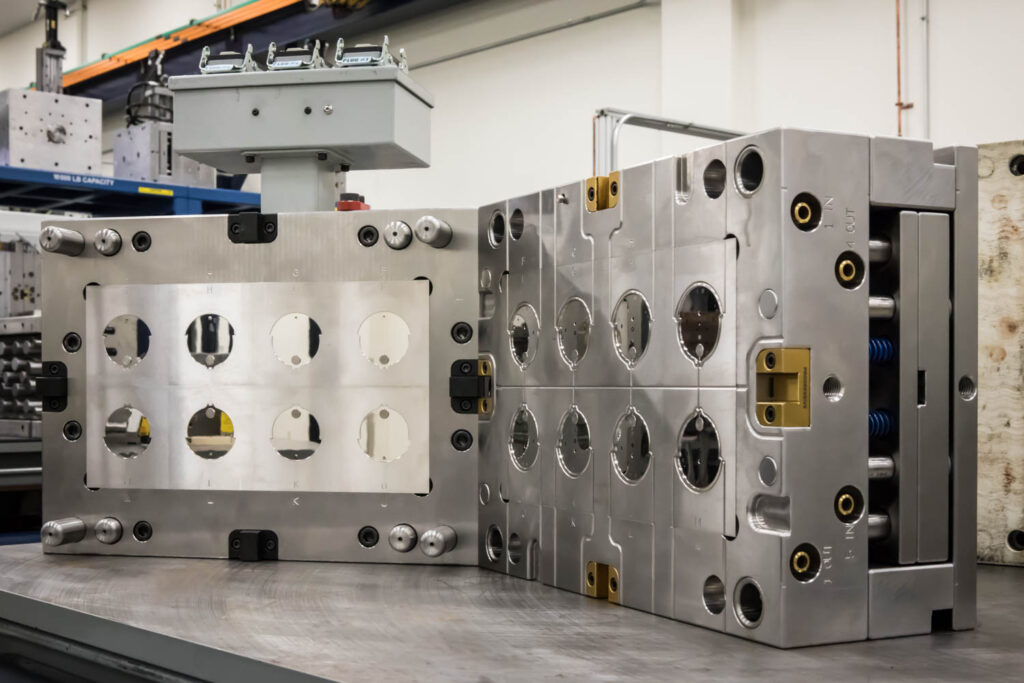

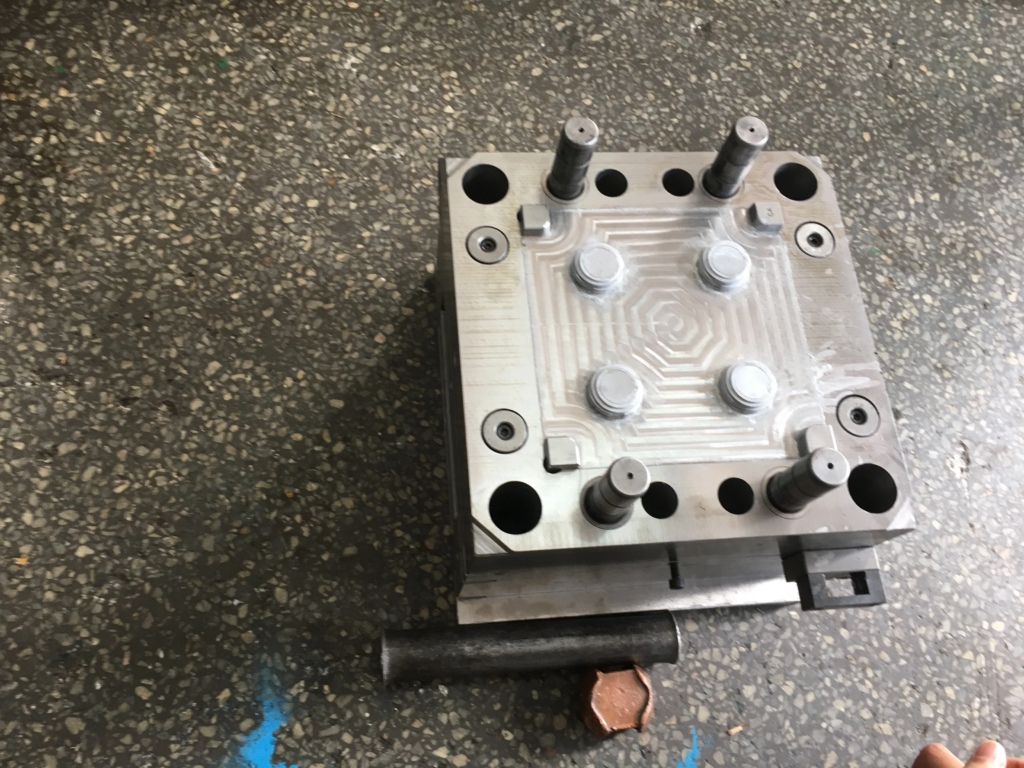

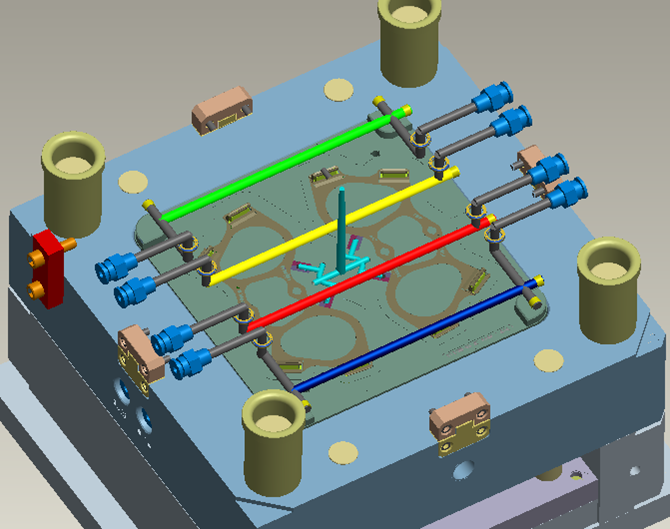

PVC Mold Fabrication and Tooling Solutions

PVC (Polyvinyl Chloride) is widely used in industries such as construction, automotive, medical, and consumer goods due to its durability, chemical resistance, and cost-effectiveness. Advanced mold fabrication and tooling solutions are essential for manufacturing high-quality PVC components with precision, efficiency, and minimal defects. A. Material Selection for Molds PVC molding requires durable mold materials to […]

PVC Mold Fabrication and Tooling Solutions Read More »