Injection Molding Tooling and Mold Design

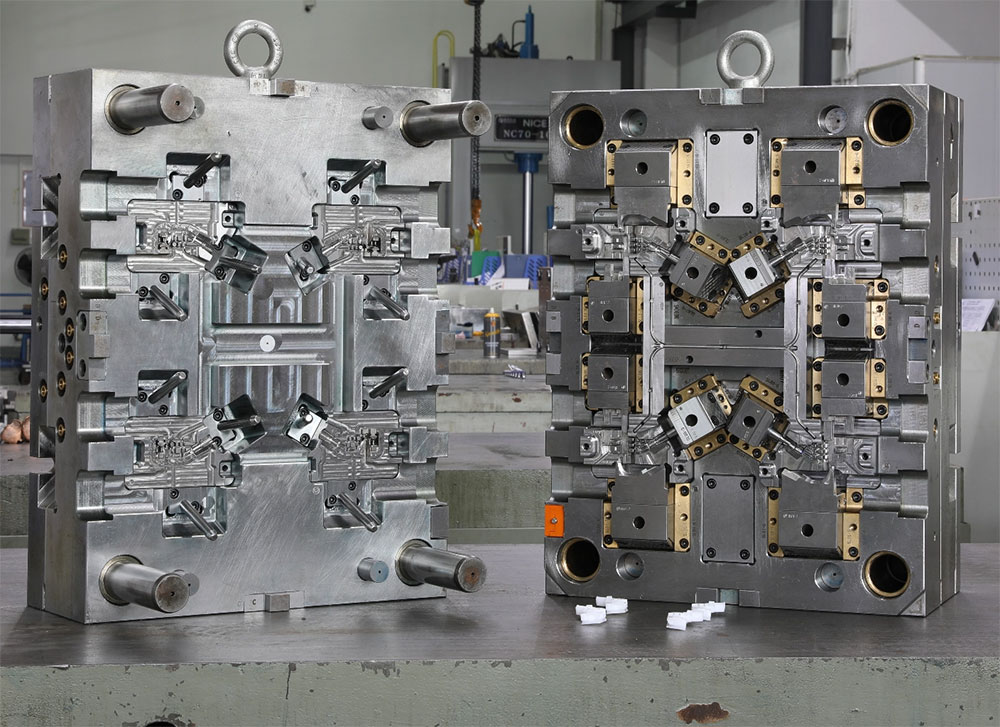

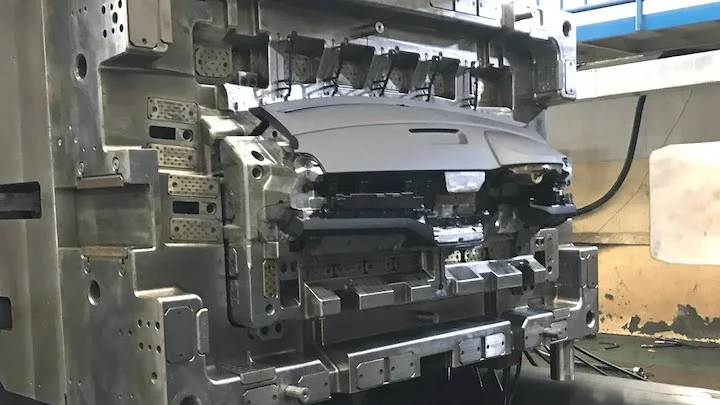

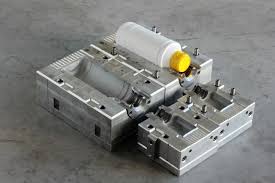

Tooling and mold design are pivotal components of the injection molding process, directly influencing the efficiency, cost, and quality of the final product. Molds act as the framework where molten plastic is shaped into precise, complex parts. A well-designed mold ensures repeatability, minimizes production defects, and supports high-volume manufacturing with tight tolerances. Key Considerations in […]

Injection Molding Tooling and Mold Design Read More »