High-Precision Molds for Automotive Electronics

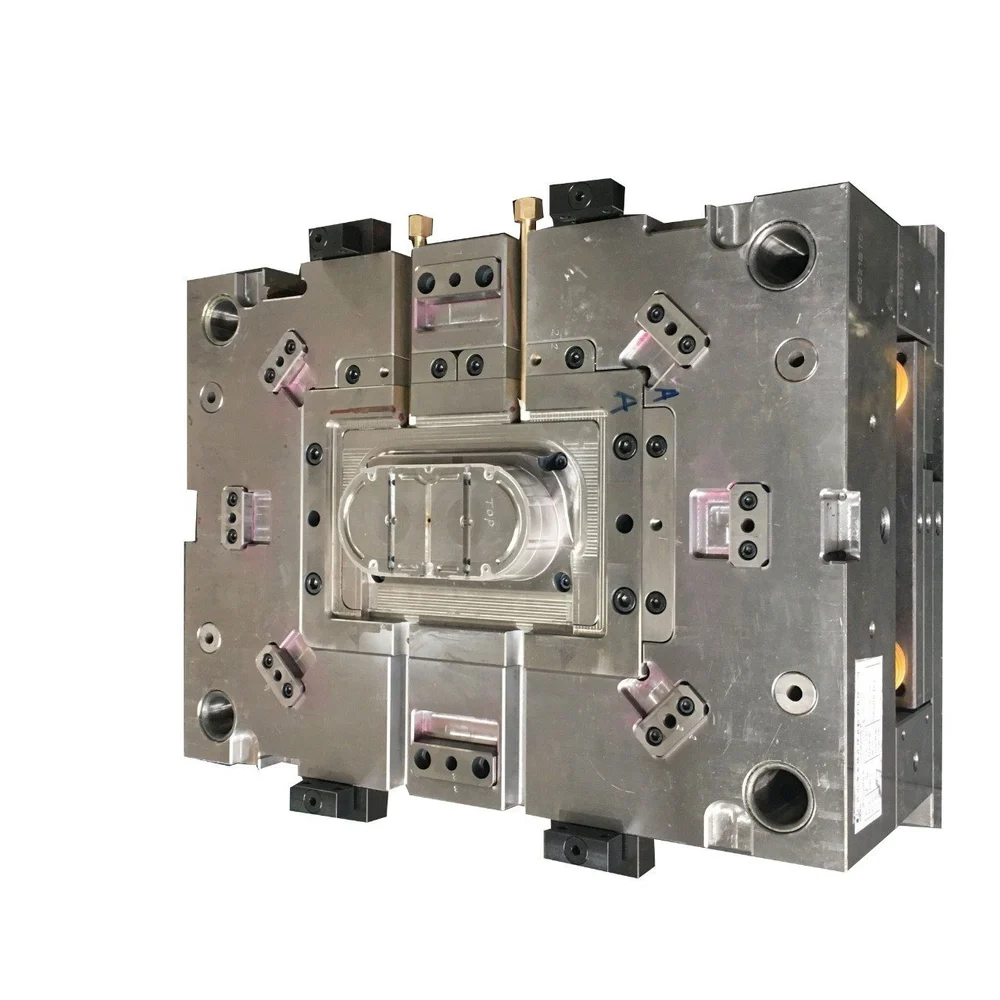

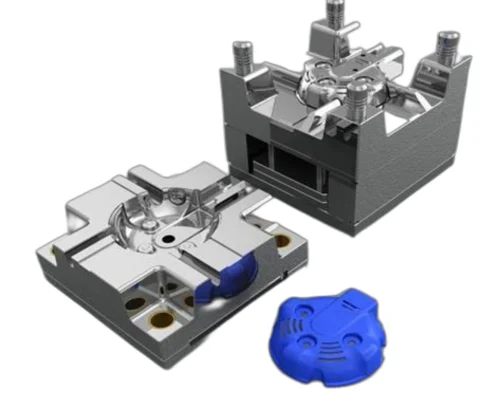

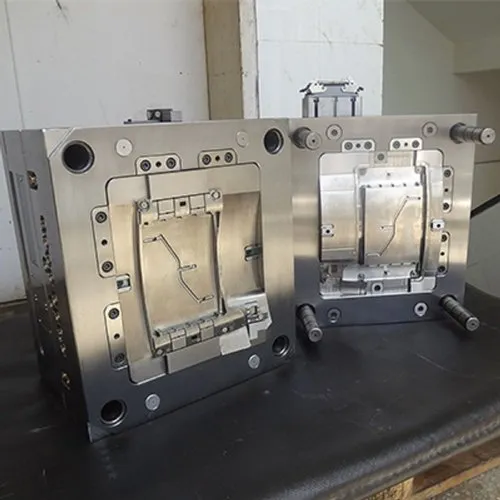

High-precision molds play a critical role in the manufacturing of automotive electronics. As the automotive industry continues to evolve, the demand for more advanced and reliable electronics within vehicles is on the rise. From infotainment systems and navigation to safety features like airbag sensors and electronic control units (ECUs), automotive electronics are integral to modern […]

High-Precision Molds for Automotive Electronics Read More »