High-Precision Molding for PVC Products

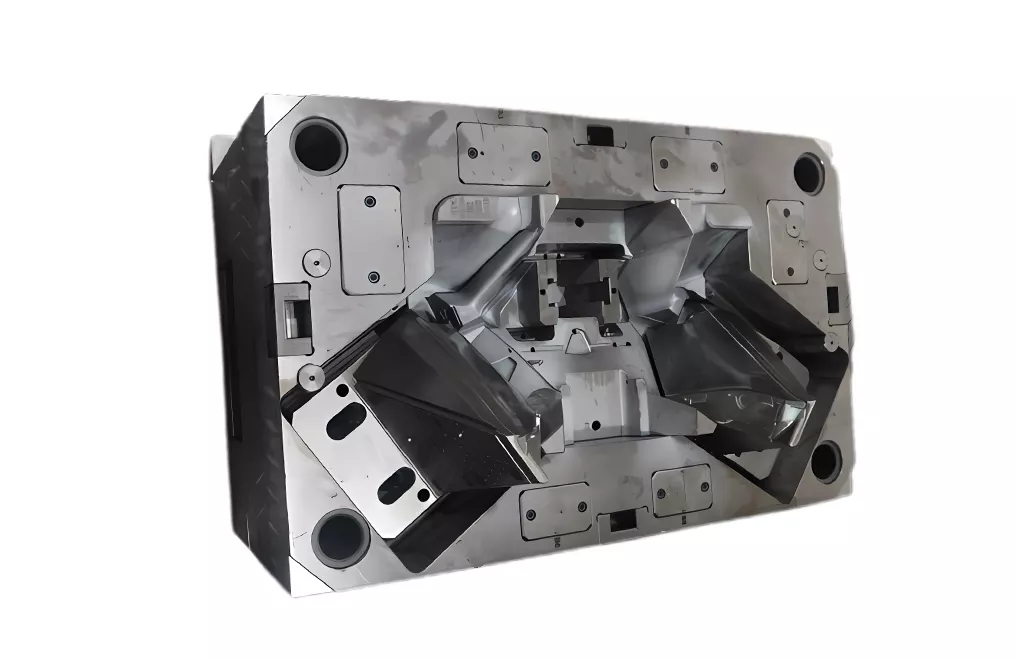

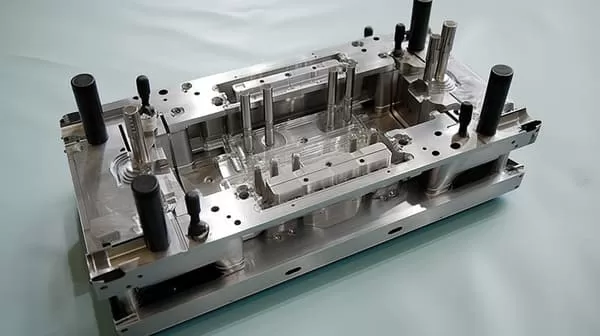

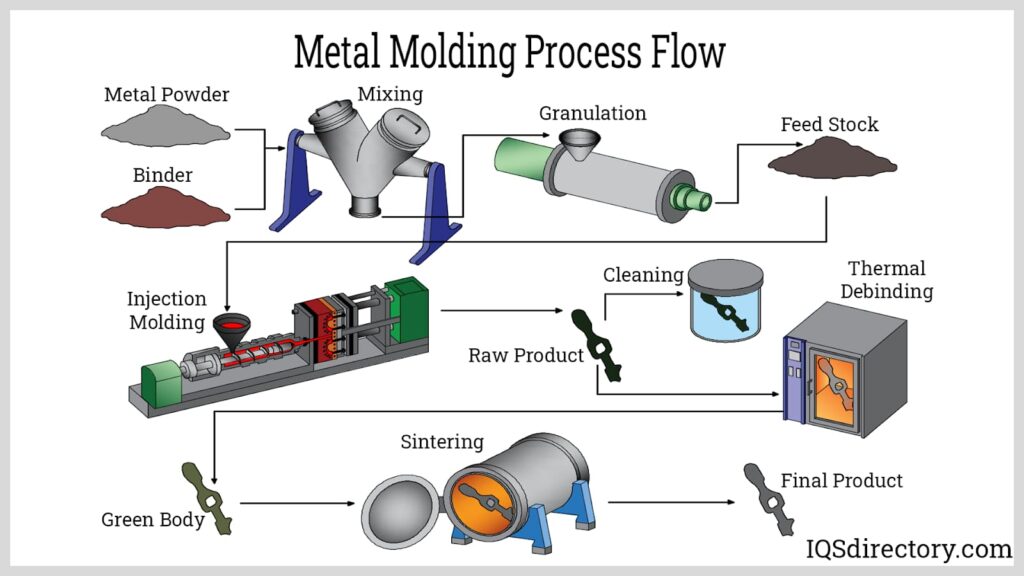

High-precision molding is a specialized manufacturing process that ensures consistent, accurate, and high-quality production of polyvinyl chloride (PVC) components. This technique is essential for industries where tight tolerances, superior surface finishes, and dimensional accuracy are critical, such as automotive, medical, electronics, and consumer goods. What is High-Precision Molding? High-precision molding refers to the use of […]

High-Precision Molding for PVC Products Read More »