Innovations in Plastic Injection Molding

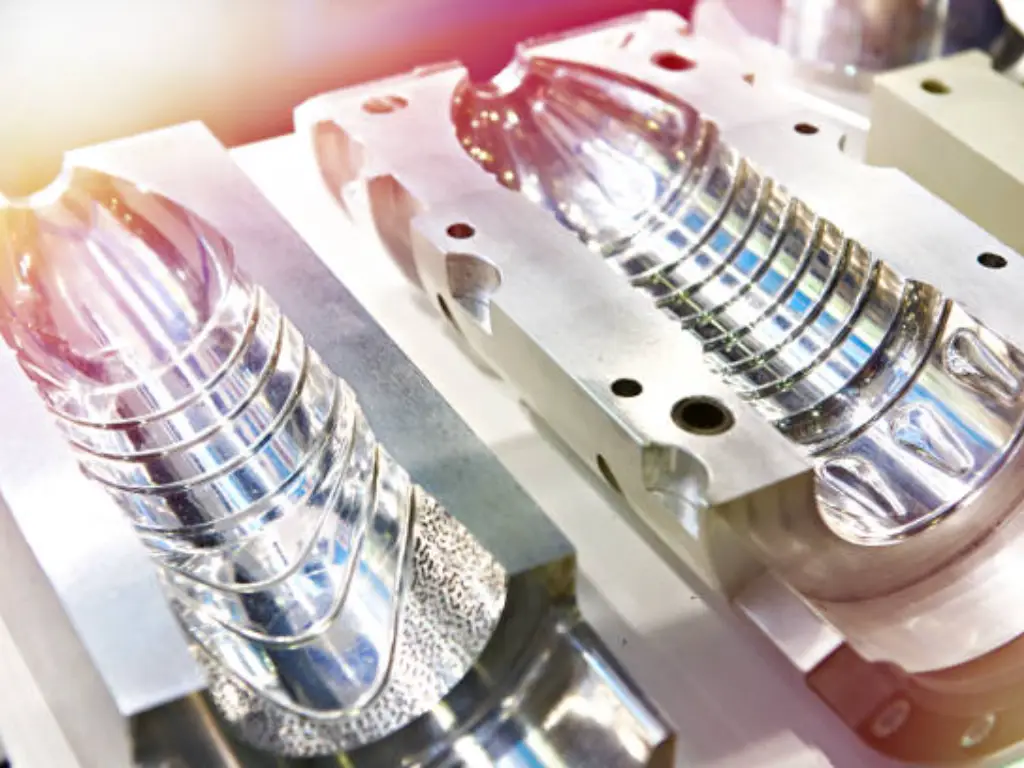

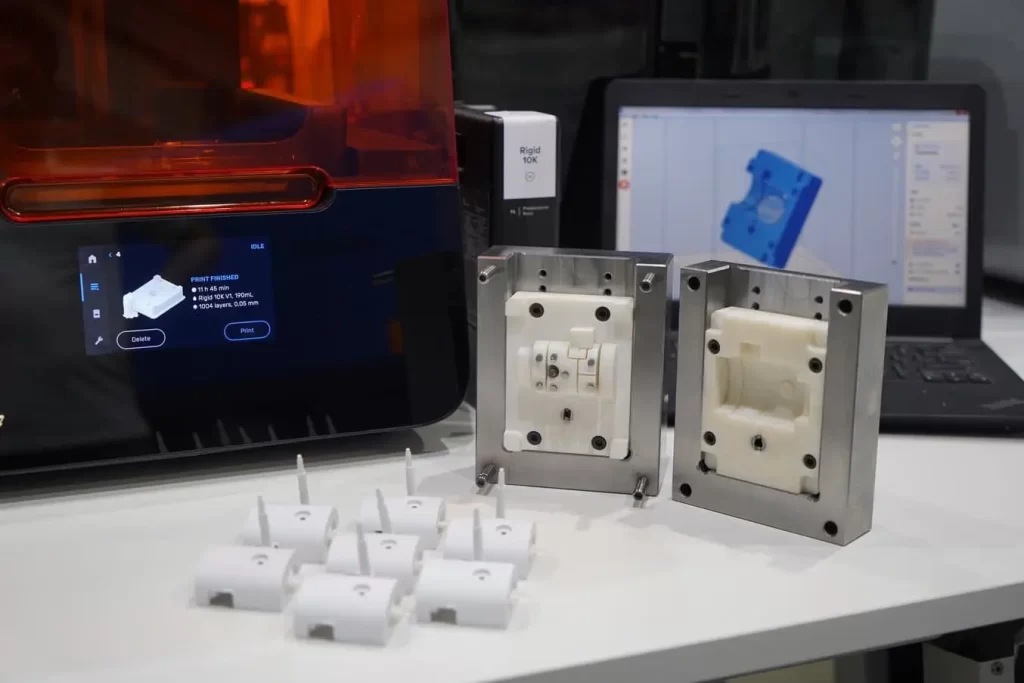

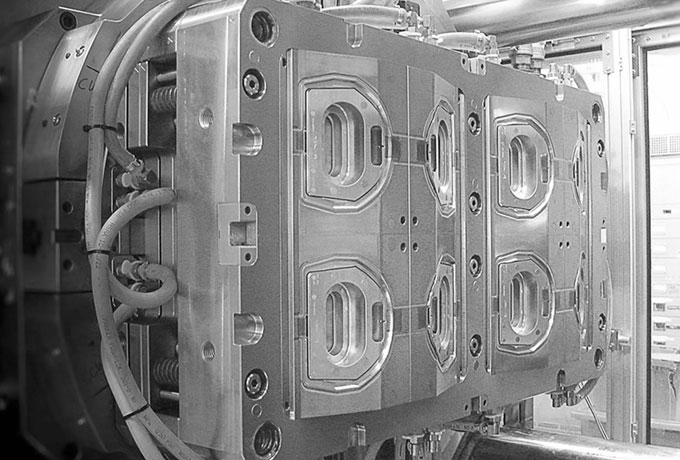

Plastic injection molding, a core process in the manufacturing of plastic products, has seen significant innovations in recent years. These advancements have improved production efficiency, design capabilities, material performance, and environmental sustainability. Below are the key innovations shaping the future of plastic injection molding: 1. Advanced Materials Biodegradable and Recycled Plastics: The use of eco-friendly […]

Innovations in Plastic Injection Molding Read More »