Custom mold design for PVC products is an essential process in manufacturing, enabling the production of high-quality, durable, and precise components. PVC (Polyvinyl Chloride) is widely used in various industries for its versatility, low cost, and durability. Whether it’s for pipes, fittings, flooring, or medical devices, the design of the mold must account for the unique characteristics of PVC and the specific demands of the final product. The custom mold design process involves multiple factors, from material selection to the geometry of the mold, ensuring that the PVC is processed efficiently and produces parts with the desired performance and appearance.

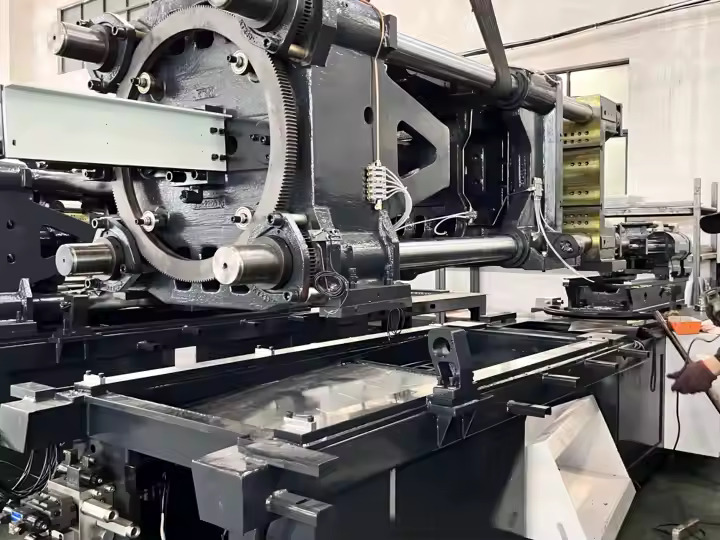

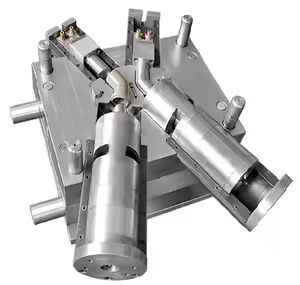

The first step in custom mold design is understanding the particular requirements of the PVC product. PVC behaves differently from other thermoplastics, particularly in terms of its cooling and shrinkage properties. The design of the mold must take into account these characteristics to ensure uniform flow during the injection molding process. Proper venting is critical, as trapped air can lead to imperfections such as air bubbles or voids in the molded part. Additionally, because PVC has a relatively slow cooling rate, the mold must be designed with an efficient cooling system to ensure consistent temperature control throughout the process. If not managed correctly, uneven cooling can cause warping or dimensional inaccuracies in the final product.

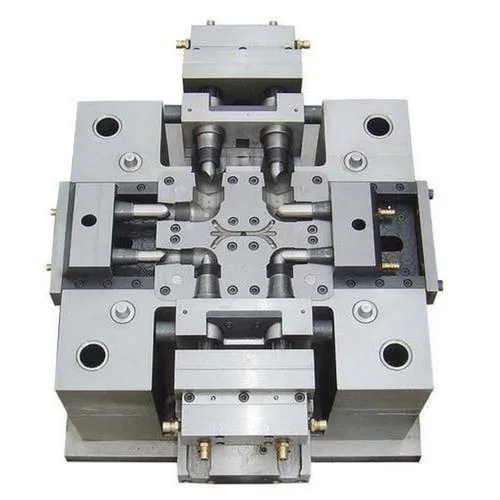

The design of the mold cavity itself must also reflect the product’s geometry, ensuring that the PVC flows smoothly into all areas of the mold. Gate design is crucial here; the gate is the entry point through which the molten PVC is injected into the mold. Its size and location must be carefully chosen to optimize the material flow, reduce the potential for defects, and minimize visible marks on the finished product. The placement of cooling channels is equally important to ensure even temperature distribution and to reduce cycle time. A well-designed mold can help achieve faster production times and better material efficiency, contributing to overall cost savings