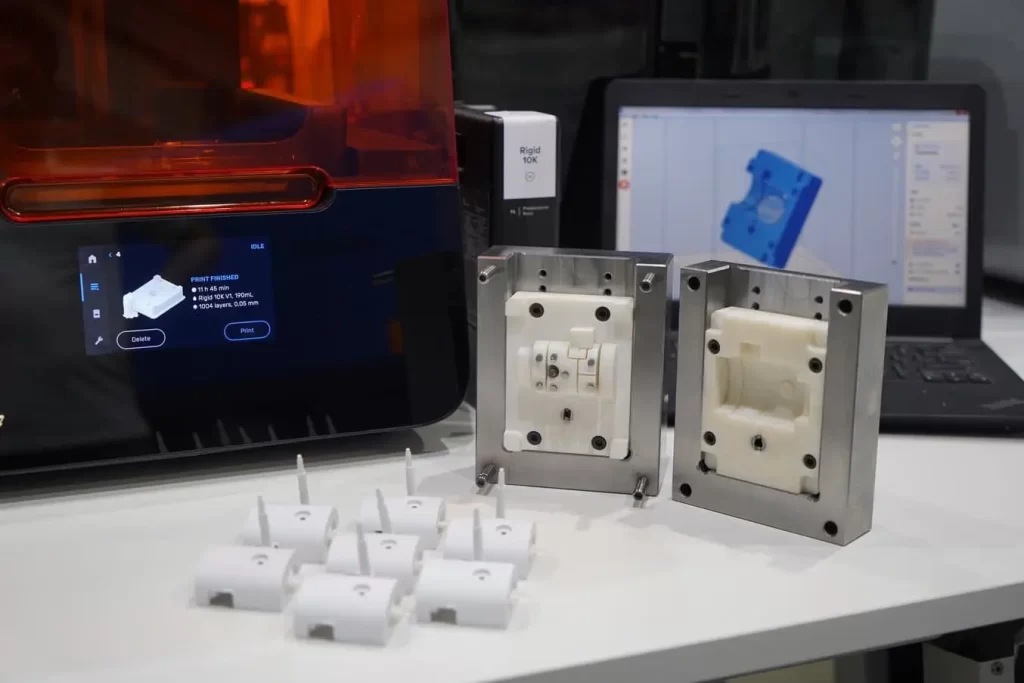

Injection molding is a widely used manufacturing process for producing plastic parts by injecting molten material into a mold. Its efficiency and precision make it ideal for both low-volume and high-volume production, though the approaches and economics differ significantly between the two.

1. Tooling Differences

Low-Volume Production:

Tooling Material: Often uses softer, less durable materials like aluminum or soft steel (P20).

Tooling Cost: Lower initial cost; faster and cheaper to fabricate.

Lead Time: Shorter mold production time—ideal for rapid prototyping or pilot runs.

High-Volume Production:

Tooling Material: Hardened steel (H13, S7), built for longevity and durability.

Tooling Cost: High upfront investment due to complex machining and durability.

Lead Time: Longer setup and testing times, but sustainable over millions of cycles.

2. Cost Considerations

Low-Volume:

Per-Part Cost: Higher per unit due to less amortization of tooling costs.

Best For: Prototyping, bridge tooling, market testing, and custom/specialty products.

Flexibility: Easier to modify tooling or switch designs between runs.

High-Volume:

Per-Part Cost: Very low due to economies of scale.

Best For: Mass production of consistent parts (e.g., automotive, packaging).

ROI: Tooling cost is spread over a large quantity, making it more economical in the long run.

3. Production Speed & Cycle Time

Low-Volume:

Faster mold fabrication but may use slower or manual processes for molding.

Shorter runs mean quicker changeovers between projects.

High-Volume:

Optimized for speed and efficiency with automated processes and robotics.

Longer cycle time investment pays off with high-speed, high-output systems.

4. Design and Material Flexibility

Low-Volume:

More design flexibility due to simpler molds.

Easier to test various materials, geometries, and modifications.

High-Volume:

Requires robust design validation upfront to avoid costly mistakes.

Limited design changes once production starts due to mold rigidity.

5. Applications

Low-Volume:

Startups and R&D

Medical device prototyping

Aerospace and defense (custom, low-quantity parts)

Market validation

High-Volume:

Consumer electronics

Automotive parts

Packaging (bottles, caps, containers)

Household goods