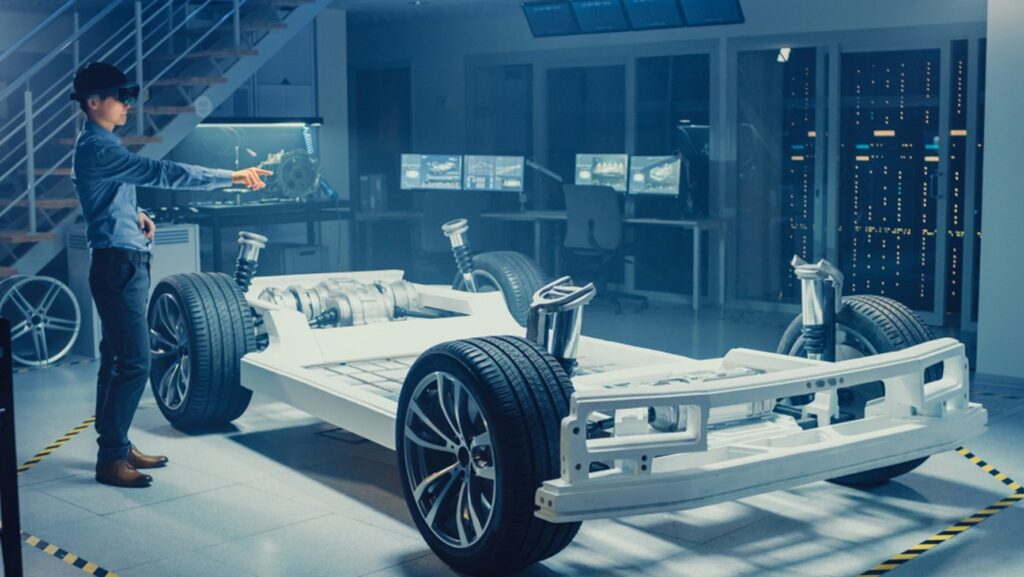

Augmented Reality (AR) is revolutionizing the automotive industry, especially in the domain of tooling, by blending digital information with the physical world. By overlaying computer-generated visuals, instructions, and data onto real-world environments, AR enhances the precision, efficiency, and safety of automotive tooling operations.

Applications of AR in Automotive Tooling

Tool Design and Simulation

AR allows engineers to visualize 3D models of tools in real-time before physical prototypes are built.

It helps simulate how a tool will interact with vehicle components, enabling better ergonomic and functional design.

Modifications and iterations can be performed digitally, reducing design cycles.

Assembly Line Tool Guidance

Technicians can use AR headsets or smart glasses to receive step-by-step guidance for assembling or using specific tools.

Visual overlays highlight where and how a tool should be applied, reducing errors and improving quality control.

Real-time instructions are especially helpful for complex or infrequently performed tasks.

Maintenance and Troubleshooting

AR can display internal tool mechanisms or highlight areas needing maintenance without disassembly.

Technicians can access interactive repair manuals and diagnostic overlays, improving response time and accuracy.

Training and Skill Development

New employees can be trained using AR simulations of tooling procedures in a controlled environment.

AR-based training reduces the need for physical components and tools, lowering costs and risk.

Trainees can practice tool handling with real-time feedback, enhancing learning outcomes.

Quality Inspection

AR systems can project measurement data and tolerance indicators directly onto tools and components.

Real-time comparison with CAD models helps detect misalignments or defects immediately.

Enhances the precision of manual inspections and reduces the need for rework.

Benefits of AR in Automotive Tooling

Improved Accuracy: Reduces human error by providing real-time, visual instructions.

Cost Savings: Cuts down the need for physical prototypes, printed manuals, and repeated training.

Faster Development: Accelerates tooling design, testing, and deployment processes.

Enhanced Safety: Provides situational awareness and procedural compliance during tool operation.

Real-time Collaboration: Enables remote experts to guide on-site technicians through AR interfaces.

Challenges and Considerations

Initial Investment: High upfront costs for AR hardware and software development.

Integration Complexity: Seamless integration with existing CAD systems, ERP platforms, and shop floor tools is required.

User Adaptability: Technicians need training to adapt to AR-based systems effectively.

Data Security: Real-time AR systems must ensure data protection, especially when connected to cloud or IoT platforms.

Future Outlook

The use of AR in automotive tooling is expected to grow with advancements in wearable technology, AI, and IoT. As AR becomes more accessible and affordable, even smaller manufacturers are likely to adopt it for tool optimization and workforce empowerment. In the long run, AR will be integral to the smart factory concept and Industry 4.0 initiatives.

Conclusion

Augmented Reality is reshaping the way tooling is approached in the automotive sector. By bridging the gap between digital precision and physical execution, AR enhances productivity, quality, and safety in automotive tooling operations. As technology matures, its impact will only deepen, making it a vital component of the automotive industry’s future.