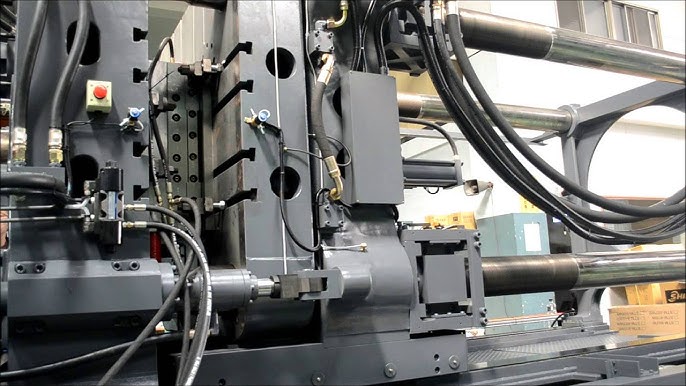

PVC (Polyvinyl Chloride) is a widely used thermoplastic polymer in various industries, including automotive, construction, healthcare, and consumer goods. The injection molding process is crucial for manufacturing PVC products with precision and consistency. However, traditional PVC injection molding machines can be energy-intensive, leading to high operational costs and environmental concerns. As a result, the industry is moving towards energy-efficient PVC injection molding machines to promote sustainability and cost-effectiveness.

What Makes a PVC Injection Molding Machine Energy-Efficient?

Servo Motor Systems

Energy-efficient machines often use servo motors instead of traditional hydraulic systems. Servo motors provide precise control over the machine’s movements, reducing energy consumption by up to 60% compared to conventional machines.Variable Frequency Drives (VFD)

These systems adjust the motor speed according to the load requirement, significantly minimizing power waste during idle or low-load operations.Optimized Heating Systems

Advanced machines utilize induction or infrared heating systems that reduce thermal loss, enhancing heating efficiency and lowering electricity usage.Smart Control Systems

Modern machines incorporate intelligent controllers with real-time monitoring and auto-adjustment capabilities. These systems optimize cycle times, reduce downtime, and improve overall energy management.Efficient Cooling Mechanisms

Integrated cooling systems, such as closed-loop water cooling or optimized fan cooling, help maintain machine temperature without excessive energy use.

Benefits of Using Energy-Efficient Machines

Reduced Operational Costs: Significant savings on energy bills over the machine’s lifecycle.

Lower Carbon Footprint: Contributes to corporate sustainability goals by minimizing greenhouse gas emissions.

Improved Productivity: Faster cycle times and precise control improve output quality and quantity.

Extended Machine Life: Reduced mechanical stress and optimized operation prolong equipment lifespan.

Regulatory Compliance: Helps meet increasing environmental regulations and energy standards.

Applications of PVC Injection Molding

Energy-efficient machines are used to manufacture a wide range of PVC-based products, including:

Electrical conduits and fittings

Window and door profiles

Medical tubing and devices

Automotive interior components

Plumbing pipes and connectors

Choosing the Right Energy-Efficient PVC Injection Molding Machine

When selecting a machine, consider the following:

Clamping force and shot size requirements

Compatibility with PVC-specific processing needs (e.g., corrosion-resistant components)

Energy efficiency certifications or ratings

Maintenance and support services

Automation and integration capabilities

Conclusion

Energy-efficient PVC injection molding machines represent a vital advancement in plastic manufacturing, merging environmental responsibility with operational efficiency. By investing in such technology, manufacturers not only cut costs but also contribute to a more sustainable future. The transition to energy-efficient solutions is not just an industry trend—it’s a strategic imperative for modern production.