Cosmetic moulding, especially in plastic injection moulding, requires high precision and aesthetic quality. Even minor surface defects can render a product unacceptable for consumer use. Below are some of the most common defects encountered in cosmetic moulding along with their likely causes:

1. Flow Lines

Description: Streaks or patterns (often wavy) that appear on the surface, usually around gates or thin sections.

Causes:

Low injection speed or pressure

Material temperature too low

Poor gate design or improper gate location

Mold temperature too low

2. Sink Marks

Description: Small depressions or dimples on thick sections of the moulded part.

Causes:

Insufficient cooling time

Inadequate packing pressure

Thick part geometry without sufficient ribbing

Mold temperature too high

3. Weld Lines (Knit Lines)

Description: Lines or seams where two flow fronts meet, often visible as a cosmetic imperfection.

Causes:

Low melt or mold temperature

Low injection speed

Poor venting

Design features that force multiple flow fronts to converge

4. Jetting

Description: Worm-like flow patterns on the part’s surface.

Causes:

High injection speed with low melt viscosity

Improper gate design (too small or in the wrong location)

Inadequate mold temperature

5. Blush Marks

Description: Whitish or dull area, usually near the gate.

Causes:

Excessive shear stress due to high injection speed

Improper gate size or design

Material degradation

6. Splay (Silver Streaks)

Description: Streaks or lines, typically silvery, that appear on the part’s surface.

Causes:

Moisture in the resin

Degraded material due to excessive heat

Air entrapment

Contaminated resin

7. Burn Marks

Description: Dark, often black or brown, discoloration caused by trapped gases.

Causes:

Inadequate venting

Excessive injection speed or pressure

Trapped air overheating due to compression

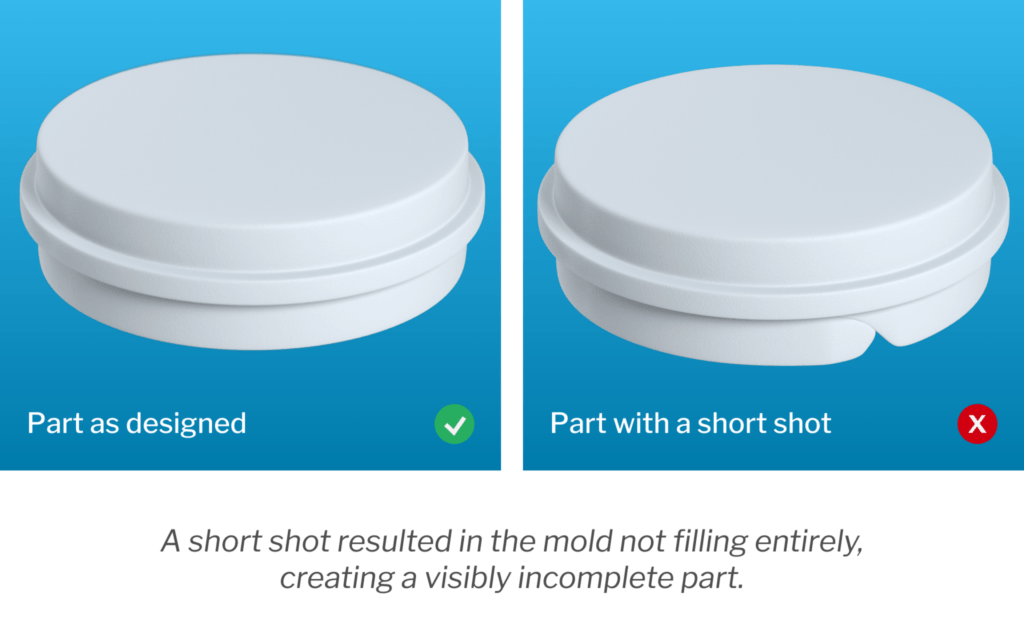

8. Short Shots

Description: Incomplete filling of the mold cavity, leading to missing sections.

Causes:

Low injection pressure or speed

Low melt or mold temperature

Flow restrictions due to poor part design

Inadequate venting

9. Flash

Description: Excess material that escapes from the mold cavity and solidifies on the parting line.

Causes:

Worn or damaged mold components

Excessive injection pressure

Improper clamping force

Mold not properly aligned

10. Warping

Description: Twisting or deformation of the part after cooling.

Causes:

Uneven cooling across the part

Incorrect mold temperature

Inconsistent wall thickness

High shrinkage materials

Preventive Measures

To minimize cosmetic defects:

Maintain optimal processing parameters (temperature, pressure, speed).

Ensure proper mold design and maintenance.

Use quality raw materials and dry them thoroughly.

Design parts with uniform wall thickness and proper flow paths.

Use simulation software to predict potential defects before manufacturing.