Computer-Aided Design (CAD) has become an essential tool for designing PVC molds, offering unparalleled precision, efficiency, and adaptability. These molds, used in applications such as plumbing, automotive components, and packaging, require detailed attention to material flow, geometry, and manufacturing constraints, all of which CAD addresses effectively.

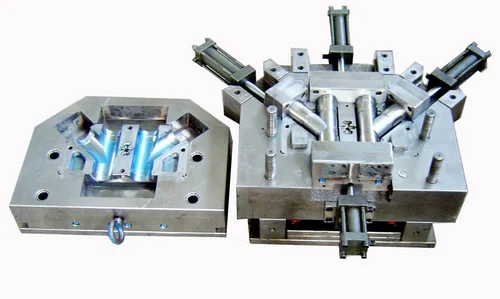

Enhanced Mold Geometry Design

CAD tools allow for the creation of complex mold geometries with high precision, essential for intricate PVC products. Engineers can design cavities, cooling systems, and gating mechanisms with exact specifications, ensuring consistent product quality in mass production.

Material Behavior Simulation

Modern CAD software integrates simulation capabilities to predict the flow and cooling behavior of molten PVC within the mold. This helps identify and address issues like material shrinkage, warping, or uneven cooling, enabling engineers to optimize designs before physical prototypes are created.

Design Customization and Flexibility

PVC molds often need customization to accommodate variations in product designs or specific client requirements. CAD systems support parametric modeling, allowing designers to quickly adjust dimensions or features without starting from scratch. This flexibility is crucial for meeting diverse production needs.

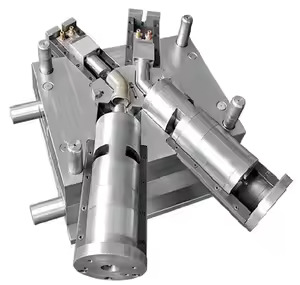

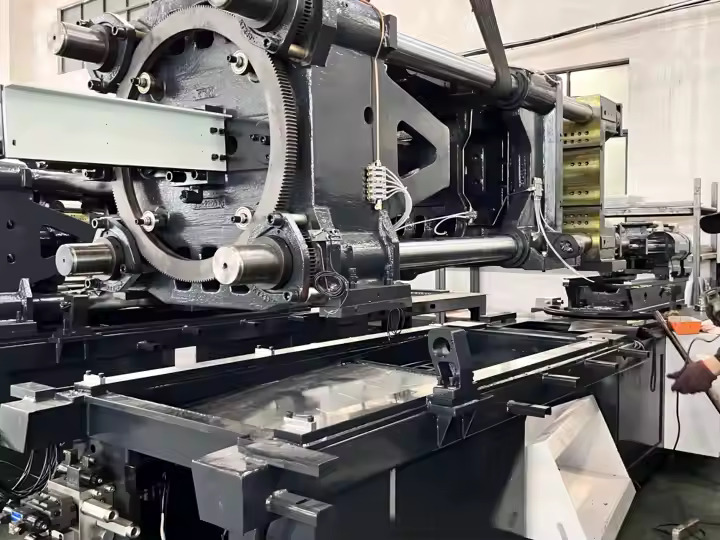

Integration with CAM and CNC

CAD designs are seamlessly integrated into Computer-Aided Manufacturing (CAM) and CNC machining processes, ensuring accurate and efficient mold manufacturing. Tool paths and machining parameters can be directly derived from CAD models, reducing errors and production time.

Cost and Time Efficiency

By enabling virtual prototyping and iterative design, CAD significantly reduces the need for physical trials and errors. This accelerates the mold development process, minimizes material wastage, and lowers overall costs, making it a cost-effective solution for designing PVC molds.

Collaboration and Cloud-Based Design

Cloud-enabled CAD platforms facilitate real-time collaboration among designers, engineers, and manufacturers. This improves communication, streamlines the design process, and ensures alignment across all stages of mold development.

Support for Sustainable Practices

CAD tools contribute to sustainability by enabling designs that optimize material use and minimize waste. For PVC, which is sensitive to environmental concerns, designing molds that reduce material waste aligns with industry trends toward greener practices.