Polyvinyl chloride (PVC) is a popular material in the toy industry, and molds designed for PVC are integral to creating a wide range of toys. PVC is valued for its versatility, durability, and ability to be molded into intricate shapes, making it ideal for manufacturing toys that are safe, colorful, and long-lasting. From action figures and dolls to inflatable toys and educational tools, PVC molds enable the production of diverse and appealing products for children.

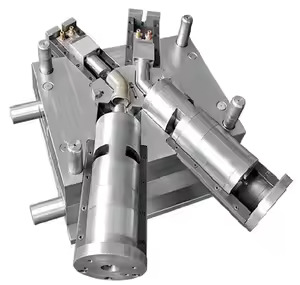

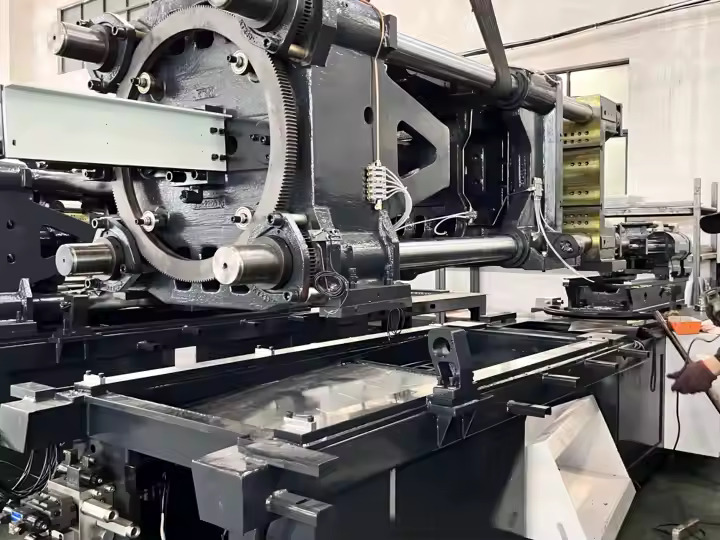

PVC molds are typically used in injection molding, blow molding, or rotational molding processes, depending on the toy’s design and functionality. These molds are crafted with precision to achieve high levels of detail, ensuring that toys meet aesthetic standards and functional requirements. For example, injection molds may feature fine details to create realistic facial expressions on dolls or intricate textures on toy surfaces. Blow molds are used for hollow toys like balls or inflatables, while rotational molds are ideal for large, hollow items such as playhouses or toy storage units.

The toy industry demands molds that ensure consistency, safety, and quality. Molds for PVC toys are often designed to minimize sharp edges and ensure smooth surfaces, adhering to strict safety regulations such as ASTM F963 and EN 71. These standards are critical in ensuring that toys are non-toxic, free of hazardous components, and safe for children of various age groups.

PVC molds also offer flexibility in terms of color and finish. Toys can be produced in a wide array of vibrant colors, glossy or matte finishes, and even soft-touch textures, enhancing their appeal and playability. Additionally, the durability of PVC allows toys to withstand rough handling, making them suitable for long-term use.

Advanced manufacturing technologies, including 3D prototyping and computer-aided design (CAD), play a crucial role in the development of PVC molds. These technologies shorten the design-to-production timeline and enable customization for unique toy concepts. With growing environmental concerns, innovations in PVC recycling and the use of phthalate-free PVC are also influencing the design of molds, ensuring the toy industry remains sustainable and compliant with evolving standards.