Injection molding plays a crucial role in manufacturing high-performance fuel system components, addressing the stringent requirements for precision, durability, and chemical resistance. These components, which include fuel tanks, connectors, valves, and sealing elements, must meet strict industry standards to ensure safety and efficiency in automotive and industrial applications.

Material Selection for Fuel System Components

One of the most critical aspects of injection molding for fuel systems is the selection of materials. Engineers often use high-performance thermoplastics such as polyamides (nylon), polyoxymethylene (POM), and fluoropolymers, which offer excellent resistance to fuels, oils, and high temperatures. These materials also provide strength, lightweight characteristics, and compatibility with intricate designs, which are essential for efficient fuel system performance.

Precision and Consistency

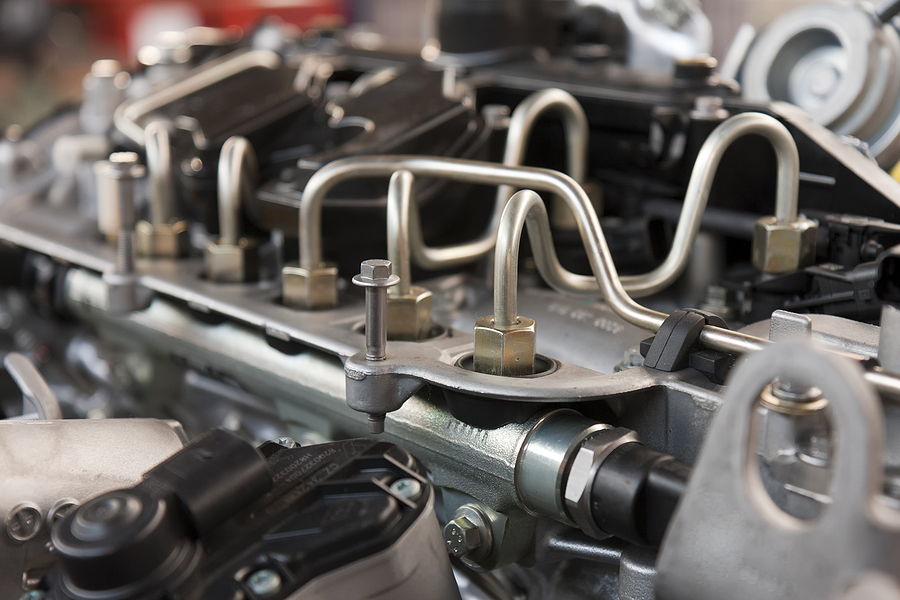

Fuel system components must meet tight tolerances to ensure leak-free and reliable operation under high-pressure conditions. Injection molding provides the precision needed for complex geometries and intricate designs. Advanced molding techniques, such as gas-assisted and multi-shot molding, allow manufacturers to produce lightweight, robust parts with integrated functionalities, reducing the need for secondary assembly processes.

Resistance to Environmental and Mechanical Stress

Fuel system components are exposed to harsh environments, including extreme temperatures, vibration, and corrosive substances. Injection molding ensures the production of parts with uniform material distribution and structural integrity, enabling them to withstand these challenges. The process also supports the production of components with enhanced durability and a long service life.

Cost-Effective Manufacturing

Injection molding is a highly efficient manufacturing method, particularly for high-volume production. By automating the molding process, manufacturers can achieve consistent quality, reduce waste, and minimize production costs. Additionally, the use of recyclable materials in molding aligns with sustainability goals, which are increasingly important in the automotive industry.