3D printing, also known as additive manufacturing, has revolutionized various industries by enabling rapid prototyping, customization, and complex geometrical fabrications. One of the significant applications of 3D printing is in mould making — a critical process in manufacturing for mass-producing parts through casting, injection molding, or other forming techniques.

Traditionally, mould making involves time-consuming and expensive processes using CNC machining, hand sculpting, or tooling. However, 3D printing offers an efficient, flexible, and cost-effective alternative.

Applications of 3D Printing in Mould Making

Prototype Moulds

Used for testing form, fit, and function before creating final production moulds.

Ideal for short-run production or validating designs quickly.

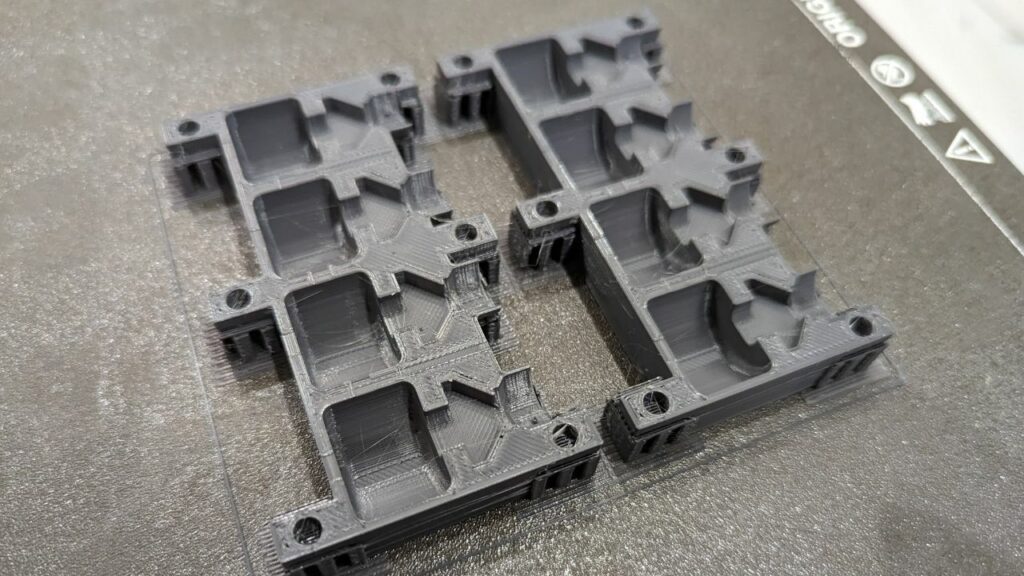

Direct Mould Printing

Moulds are printed directly using materials like resin, plastic, or even metal.

Suitable for low-volume production or custom applications.

Mould Inserts

3D printed inserts can be placed within traditional moulds to introduce complex geometries.

Useful for integrating cooling channels or detailed surface textures.

Master Patterns for Silicone or Sand Casting

3D printed patterns are used to make silicone, sand, or investment casting moulds.

Enables intricate detailing without manual sculpting.

Benefits of 3D Printing in Mould Making

Speed

Drastically reduces lead time compared to conventional mould-making techniques.Cost-Effective for Low Volumes

Eliminates the need for expensive tooling, especially for prototyping or small batch runs.Design Flexibility

Allows for complex geometries, undercuts, and internal features that are difficult or impossible to machine.Customization

Ideal for bespoke or one-off moulds, especially in medical, dental, and jewelry applications.Reduced Waste

Additive manufacturing uses only the material required, minimizing waste.

Common 3D Printing Technologies Used

Fused Deposition Modeling (FDM)

Low-cost and widely accessible.

Suitable for basic prototype moulds and patterns.

Stereolithography (SLA)

High precision and fine surface finish.

Popular for silicone moulds and casting masters.

Selective Laser Sintering (SLS)

Strong and functional parts without support structures.

Good for complex and durable moulds.

Digital Light Processing (DLP)

Fast and accurate.

Excellent for dental and jewelry mould applications.

Direct Metal Laser Sintering (DMLS)

Used to create metal moulds or inserts.

Enables conformal cooling channels for efficient injection moulding.

Materials Used in 3D Printed Moulds

Photopolymer Resins – For high-detail and smooth finishes.

PLA/ABS/Nylon – Affordable and functional for prototypes.

High-Temperature Resins – Withstand the heat of injection moulding.

Metal Alloys (Steel, Aluminum) – For high-durability production moulds.

Challenges and Limitations

Durability

Some 3D printed moulds may not withstand high temperatures or pressure, especially during injection moulding.Surface Finish

Post-processing like sanding, polishing, or coating is often required for a smooth finish.Material Constraints

Limited selection of materials compared to traditional tooling.Cost for High Volumes

Not always cost-effective for large-scale manufacturing compared to traditional moulding methods.

Conclusion

3D printing in mould making offers transformative benefits in speed, cost, and design complexity. It is especially valuable for prototyping, small batch production, and custom applications. While it may not fully replace traditional mould-making methods in high-volume manufacturing, it serves as a powerful complementary tool in modern production workflows.