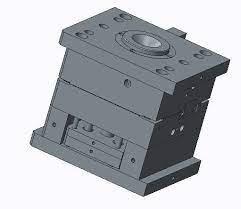

Mould flow analysis is a critical part of the plastic injection moulding process, allowing engineers to simulate and evaluate the behavior of molten plastic as it fills a mould cavity. This analysis helps identify potential issues such as air traps, weld lines, sink marks, short shots, and warpage before the actual mould is manufactured. By using mould flow simulation tools, manufacturers can optimize part design, mould design, and process parameters, leading to higher-quality products and reduced time-to-market.

Purpose of Mould Flow Simulation Tools

The primary objectives of using mould flow simulation tools are:

Optimizing gate location and number

Predicting flow behavior of the molten material

Minimizing manufacturing defects

Reducing cycle times

Improving overall part and mould quality

Reducing material waste and tooling costs

Popular Mould Flow Simulation Tools

Here are some of the most widely used mould flow analysis tools in the industry:

1. Autodesk Moldflow

Overview:

Autodesk Moldflow is one of the most popular and comprehensive mould flow analysis tools available. It offers advanced simulation capabilities for plastic injection moulding, including flow, cooling, packing, and warpage analysis.

Key Features:

Predicts and reduces manufacturing defects

Evaluates different plastic materials and processing conditions

Integration with CAD software for easy geometry import

Cloud simulation support

Use Cases: Automotive, packaging, electronics, and medical industries

2. Moldex3D

Overview:

Moldex3D is a high-performance simulation software developed by CoreTech System. It offers 3D numerical simulation capabilities and is suitable for complex part geometries and moulding processes.

Key Features:

True 3D analysis for accurate results

Simulates various processes like injection compression, gas-assisted, and co-injection moulding

Material database with thousands of thermoplastics

Embedded CAD platform for seamless design integration

Use Cases: Complex engineering components, multi-cavity and family moulds

3. SolidWorks Plastics

Overview:

SolidWorks Plastics is an add-on to SolidWorks CAD software that offers easy-to-use mould flow analysis tools for design engineers.

Key Features:

Fully integrated with SolidWorks

Focus on early-stage design validation

Ideal for evaluating gate location, flow pattern, and potential part defects

User-friendly interface suitable for non-simulation experts

Use Cases: Small to medium-sized design teams, consumer products, rapid prototyping

4. Siemens NX Mold Wizard (with Mold Flow Integration)

Overview:

Siemens NX offers advanced mould design capabilities, and when integrated with simulation tools like Moldflow or Simcenter, it provides comprehensive mould flow analysis.

Key Features:

Synchronous technology for flexible model editing

Supports advanced mould features and cooling system simulation

Parametric modelling and automation

Use Cases: Aerospace, automotive, industrial machinery

5. SIGMASOFT Virtual Molding

Overview:

SIGMASOFT focuses on simulating the complete moulding process, including thermal, mechanical, and rheological aspects. It is often used for precision components where process optimization is crucial.

Key Features:

High-fidelity simulations including mould base and cooling

Accounts for cycle-to-cycle heat accumulation

Suitable for thermosets, LSR, and metal injection moulding

Use Cases: Precision moulding, high-volume production, complex thermoset materials

Benefits of Using Mould Flow Simulation Tools

Reduced product development time and cost

Improved product quality and reliability

Better understanding of material behavior

Informed decision-making in tooling and design

Prevention of costly design changes after tooling

Conclusion

Mould flow simulation tools have become essential in modern product development, especially in industries relying on plastic injection moulding. By accurately predicting how a material will behave during moulding, these tools help engineers make smarter design choices, reduce trial-and-error iterations, and ensure the final product meets all quality and performance requirements. Selecting the right tool depends on the complexity of the part, the process being used, and the desired level of detail in simulation.