In the competitive and fast-paced housewares industry, efficiency, precision, and scalability are key. Die manufacturing, a foundational process in producing metal and plastic parts for cookware, utensils, storage solutions, and other home essentials, has undergone a significant transformation in recent years. Automation has emerged as a game-changer—revolutionizing how dies are designed, manufactured, and maintained.

What is Die Manufacturing?

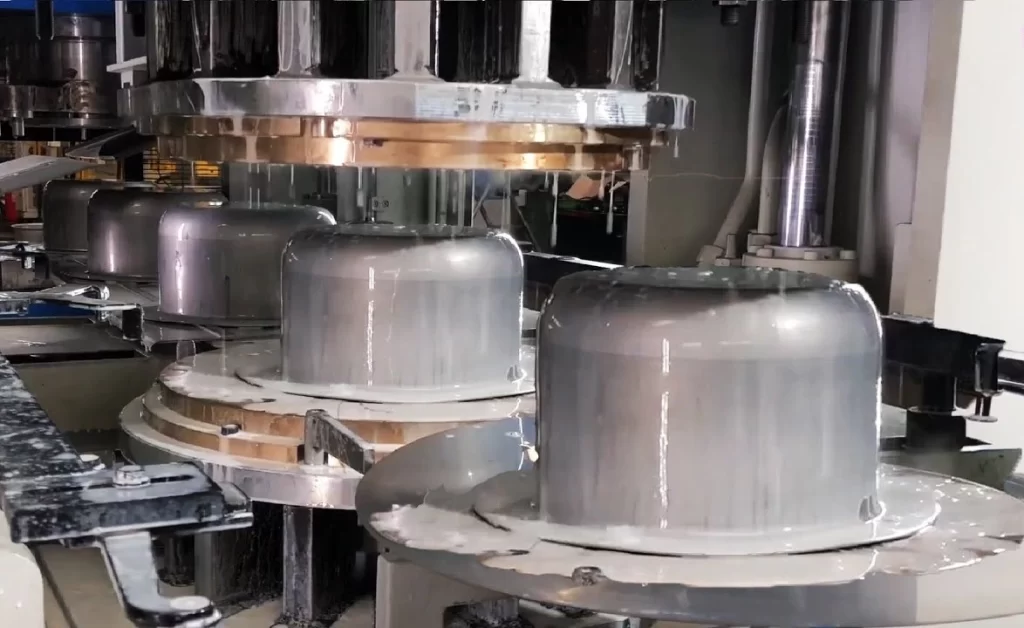

Die manufacturing involves the creation of molds or dies that are used to shape metal, plastic, or composite materials into specific forms. In housewares, dies are commonly used for:

Stamping metal sheets for pans and pots

Injection molding for plastic containers and lids

Casting for handles, knobs, or decorative elements

Precision and repeatability are crucial, as even minor inconsistencies can affect product quality and brand reputation.

Role of Automation in Die Manufacturing

Automation introduces technology-driven processes that reduce manual intervention, improve accuracy, and optimize production timelines. Here’s how it impacts die manufacturing for housewares:

1. Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM)

Automated CAD/CAM software allows for rapid prototyping and die design iteration.

Engineers can simulate die performance before production, minimizing trial-and-error.

Enhances collaboration between design and production teams for faster time-to-market.

2. CNC Machining and EDM (Electrical Discharge Machining)

CNC machines operate with high precision to shape die components consistently.

EDM is especially valuable for complex contours and hard materials used in houseware dies.

Reduces dependency on skilled manual machinists, shortening lead times and lowering error rates.

3. Robotic Handling and Assembly

Robotics automate the loading and unloading of die components and raw materials.

Enhances workplace safety by reducing human interaction with heavy or dangerous parts.

Supports lights-out manufacturing, where operations can run unattended overnight.

4. Additive Manufacturing (3D Printing)

Used to produce rapid prototypes or even complex die components with internal cooling channels.

Reduces material waste and shortens development cycles.

Ideal for small-batch or customized houseware production tools.

5. Automated Quality Inspection

Vision systems and sensors inspect die components during and after production.

AI-driven inspection tools can detect micro-defects invisible to the human eye.

Ensures consistent product quality and reduces rework or scrap.

Benefits for the Housewares Industry

✅ Faster Time-to-Market

Automation accelerates the transition from concept to finished die, enabling brands to keep up with trends and seasonal demands.

✅ Improved Product Quality

Automated systems deliver highly accurate and repeatable results, ensuring consistent form, fit, and function of houseware products.

✅ Cost Efficiency

Although automation requires upfront investment, it reduces labor costs, material waste, and downtime in the long run.

✅ Customization and Flexibility

Advanced manufacturing systems can adapt quickly to changes in design, allowing for greater product variety without major retooling.

Challenges and Considerations

High Initial Investment: Installing CNC machines, robots, and inspection systems can be capital-intensive.

Skilled Workforce Requirement: Technicians must be trained to operate and maintain automated systems.

Integration with Existing Systems: Retrofitting older factories requires careful planning and system compatibility checks.

Conclusion

Automation in die manufacturing is reshaping the housewares industry by enabling smarter, faster, and more cost-effective production. As consumer expectations rise for both design and durability, manufacturers leveraging automation will be better positioned to deliver high-quality products at scale. From smart kitchens to minimalist designs, automation ensures that the tooling behind the scenes is just as innovative as the products it helps create.