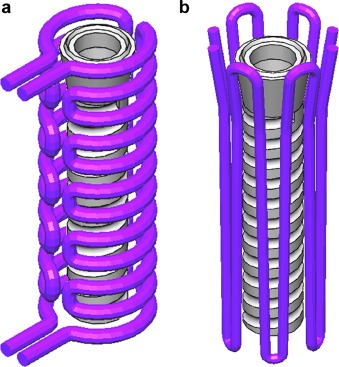

Conformal cooling is an advanced cooling technique used in injection moulding, where the cooling channels are designed to follow the contour of the mould cavity. Unlike conventional straight-drilled channels, conformal cooling lines are curved or shaped to conform closely to the geometry of the part being moulded.

This technology enables more efficient and uniform cooling, leading to improved product quality and reduced cycle times.

2. Need for Conformal Cooling

Traditional cooling methods often fall short when dealing with complex or thick-walled parts, resulting in:

Uneven cooling

Warpage or internal stresses

Long cooling times

Increased cycle times and reduced productivity

Conformal cooling addresses these challenges by placing the cooling channels closer and uniformly around critical areas of the mould.

3. How It Works

Design: Cooling channels are designed using 3D CAD software to follow the shape of the mould cavity.

Manufacturing: Since these complex channels cannot be produced with conventional drilling, additive manufacturing techniques such as Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM) are used.

Cooling Process: Water or another cooling fluid flows through these channels, removing heat more evenly and efficiently.

4. Advantages of Conformal Cooling

| Benefit | Description |

|---|---|

| Faster Cycle Times | Efficient cooling shortens the cooling phase of the cycle. |

| Improved Part Quality | Uniform cooling reduces defects such as warpage, sink marks, and residual stresses. |

| Energy Efficiency | Reduced cycle time means lower energy consumption. |

| Design Flexibility | Enables moulding of complex shapes with better control over thermal management. |

| Extended Mould Life | Reduced thermal gradients can lower mechanical stress on the mould material. |