1. Introduction to Progressive Dies

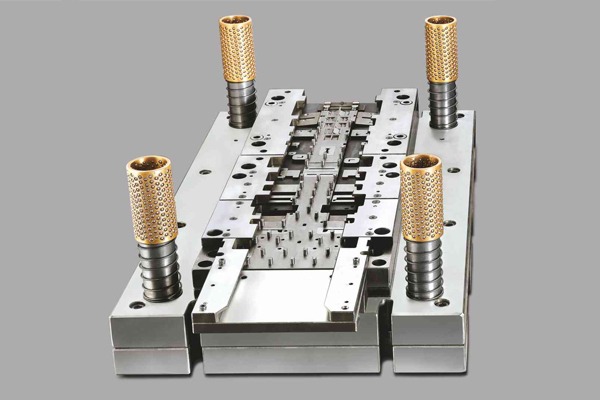

A progressive die is a type of tooling used in high-volume production to perform multiple cutting, bending, and forming operations in a single press cycle. The die consists of a series of stations, each performing a specific operation, and the sheet metal strip moves progressively through these stations with each stroke of the press.

Definition:

A progressive die is a multi-station tool where workpieces are simultaneously punched, pierced, bent, or formed at different stages as the strip advances through the die.

2. Key Components of a Progressive Die

Die Block – Contains cavities for cutting/forming.

Punch Plate – Holds punches aligned with the die cavities.

Punches – Perform piercing, cutting, or forming actions.

Stripper Plate – Removes scrap or workpieces from punches.

Guide Pins – Ensure alignment between upper and lower halves.

Pilots – Guide the strip accurately at each stage.

Stock Strip (Material Strip) – Metal strip fed into the die.

Feed Mechanism – Automatically moves the strip to the next station.

3. Progressive Die Design Process

Step-by-Step Design Flow:

Understand Product Requirements:

Analyze part drawing and tolerances.

Determine material type and thickness.

Strip Layout Design:

Determine number of stations.

Optimize material usage and minimize scrap.

Design pitch (distance between stations).

Die Set Configuration:

Define die size, alignment features, and fastening method.

Station Design:

Assign operations per station (e.g., blanking, piercing, forming).

Ensure logical progression and proper sequencing.

Punch and Die Clearance Calculation:

Based on material type and thickness to ensure clean cuts.

Component Design:

Design punches, dies, strippers, pilots, etc.

Incorporate standard parts where possible.

Simulation and Validation:

Use CAD/CAE tools to simulate strip progression.

Check for interferences, stress, and wear.

Tool Manufacturing and Testing:

Machining, assembly, and tryout.

Adjustments based on test results.

4. Advantages of Progressive Dies

High Productivity: Multiple operations in one stroke.

Reduced Labor Costs: Automation minimizes manual intervention.

Consistent Quality: Accurate and repeatable results.

Material Efficiency: Optimized strip layout reduces waste.

Lower Per-Part Cost: Ideal for mass production.

5. Applications of Progressive Dies

Progressive dies are widely used in industries requiring high-volume, precision-stamped parts. Common applications include:

Automotive: Brackets, connectors, clips, bushings.

Electronics: Terminals, lead frames, contact pins.

Appliances: Sheet metal housings, covers, fasteners.

Aerospace: Lightweight metal components.

Medical Devices: Small intricate metal parts.

6. Considerations in Progressive Die Design

Material Type: Affects tooling life and clearance values.

Press Compatibility: Die must match press tonnage and bed size.

Part Complexity: Influences the number of stations.

Maintenance: Tool design should allow easy maintenance and part replacement.

Safety Features: Include sensors or guards for operator safety.

7. Challenges and Solutions

| Challenge | Solution |

|---|---|

| Tool wear and tear | Use high-quality tool steel and coatings |

| Strip misalignment | Use precision pilots and guides |

| Burr formation | Optimize clearance and tool sharpness |

| Scrap handling | Integrate scrap cutting and disposal mechanisms |

| Die breakage during forming | Simulate forming and apply stress analysis |