Fire-retardant Polyvinyl Chloride (PVC) is widely used in molding applications where flame resistance, durability, and cost-effectiveness are crucial. This specialized PVC formulation is engineered to inhibit flame propagation, reduce smoke generation, and prevent toxic gas emissions, making it ideal for industries such as automotive, construction, electronics, and aerospace.

Advantages of Fire-Retardant PVC

- Flame Resistance – Fire-retardant additives such as chlorine, bromine, or antimony trioxide help PVC self-extinguish when exposed to fire.

- Durability & Strength – PVC maintains high impact resistance, chemical stability, and weather resistance, ensuring long-term reliability in harsh environments.

- Low Smoke & Toxicity – Specialized formulations minimize smoke and toxic gas emissions, improving safety in enclosed spaces.

- Cost-Effective – Compared to high-end fire-resistant polymers, PVC offers an affordable solution with excellent performance.

Applications of Fire-Retardant PVC in Molding

- Electrical & Electronics: Wire insulation, cable coatings, and electrical enclosures.

- Automotive: Dashboard panels, interior trims, and under-the-hood components.

- Construction: Fire-rated pipes, wall panels, and roofing sheets.

- Aerospace & Railway: Lightweight, flame-resistant interior components.

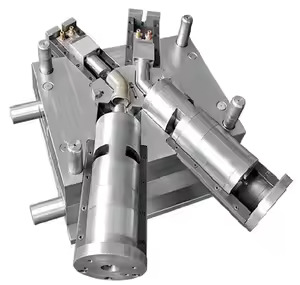

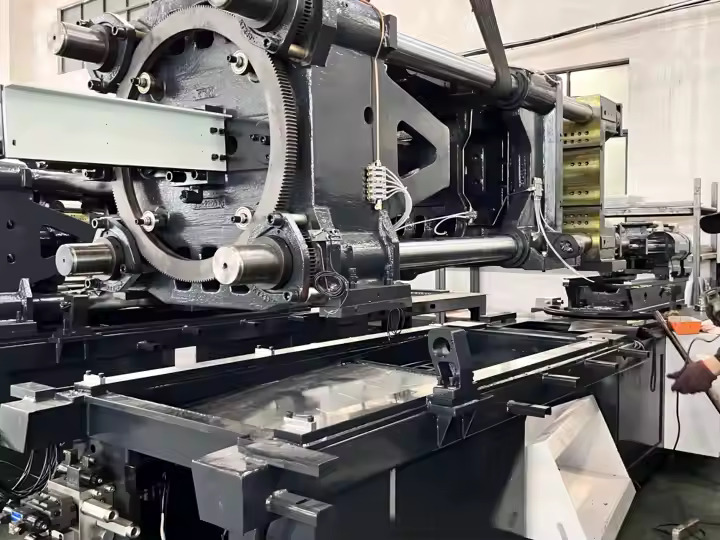

Molding Considerations

Injection and extrusion molding processes for fire-retardant PVC require precise temperature control to prevent degradation. Proper selection of mold design, processing temperature, and cooling rates ensures optimal part quality, preventing issues like warping, poor surface finish, or brittleness.

With increasing fire safety regulations across industries, fire-retardant PVC remains a go-to material for manufacturers seeking reliable, cost-effective, and flame-resistant molded components.