PVC (Polyvinyl Chloride) pipe molding is a manufacturing process used to produce a wide range of pipe fittings, connections, and custom designs from PVC material. Due to its lightweight, durable, and versatile nature, PVC pipes are extensively used in various industries, including construction, plumbing, electrical, and drainage. The molding of PVC pipes involves shaping molten PVC into specific forms, creating products that are both cost-effective and high-performance.

Techniques in PVC Pipe Molding

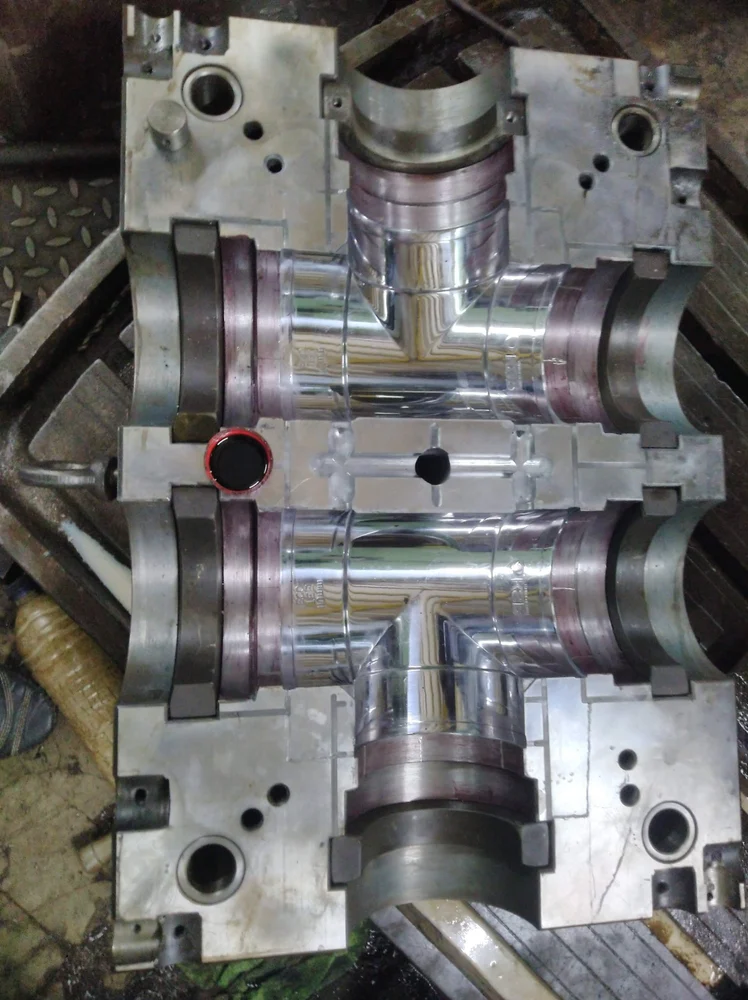

Injection Molding

Process: Injection molding involves melting PVC pellets and injecting the molten material into a mold under high pressure. This technique is commonly used for creating precise, complex, and small to medium-sized components, such as connectors, elbows, and T-joints.

Applications: This process is ideal for producing fittings and pipe parts that require high accuracy, strength, and tight tolerances. It’s widely used in plumbing and electrical conduit systems.

Advantages: High production efficiency, ability to create intricate designs, and reduced material wastage.

Extrusion Molding

Process: In extrusion molding, PVC pellets are heated and forced through a die to form long continuous shapes, like pipes or profiles. The extruded material cools and solidifies into the desired shape. After extrusion, the pipes may undergo additional processes such as cutting to length or adding other features.

Applications: This is the most common method for producing PVC pipes used in plumbing, drainage, irrigation, and electrical conduit systems.

Advantages: Cost-effective for producing long, continuous pipes, scalability, and consistency in pipe diameter and thickness.

Compression Molding

Process: Compression molding involves placing a pre-measured amount of PVC material into a heated mold cavity, where it is subjected to heat and pressure to take the shape of the mold. This process is often used for creating thicker, more robust pipe components.

Applications: Used in the manufacturing of pipe fittings, flanges, and certain structural components where a high degree of durability is required.

Advantages: Good for producing large, thick-walled components, minimal material wastage, and can produce high-strength products.

Rotational Molding

Process: In rotational molding, PVC resin is placed inside a hollow mold, which is then heated and rotated along multiple axes. As the mold rotates, the PVC material coats the inner surface of the mold and forms the desired shape as it cools and solidifies.

Applications: While not as commonly used for pipe production, rotational molding is employed for large, hollow PVC structures and products such as tanks, containers, and larger custom pipe shapes.

Advantages: Ideal for creating large, hollow components with uniform wall thickness.

Blow Molding

Process: Blow molding involves the extrusion of a PVC tube that is inflated into the shape of a mold cavity using compressed air. This technique is mainly used for creating hollow PVC items with a consistent wall thickness.

Applications: Primarily used in creating products like PVC bottles, containers, and some specialized pipe fittings.

Advantages: Suitable for hollow, complex shapes, high production rates, and low material costs.

Applications of PVC Pipe Molding

Plumbing Systems PVC pipes are widely used in residential and commercial plumbing systems due to their resistance to corrosion, ease of installation, and cost-effectiveness. Molding techniques are used to create fittings such as elbows, tees, couplings, and adapters, which are essential for connecting pipes and directing the flow of water or wastewater.

Irrigation Systems PVC pipes are commonly used in irrigation systems for agriculture and landscaping. PVC molding techniques allow for the creation of specialized fittings and connectors that help regulate and distribute water efficiently over large areas.

Electrical Conduit Systems PVC is often used for electrical conduit pipes that protect wiring in homes, buildings, and outdoor installations. Molding techniques help create various fittings like junction boxes, elbows, and connectors that enable safe and organized wiring pathways.

Drainage and Sewage Systems PVC pipe molding is also crucial in creating components for drainage and sewage systems. The ability to mold pipes and fittings to specific sizes and shapes allows for efficient and reliable wastewater management. PVC’s resistance to chemicals and moisture makes it ideal for these systems.

Industrial Applications In industrial settings, PVC pipes and molded components are used for transporting liquids, gases, and even solids. Custom-molded PVC parts are employed in various machinery, filtration systems, and fluid handling equipment, offering durability and resistance to chemical exposure.

Construction and Civil Engineering PVC pipes are frequently used in construction for stormwater drainage, ventilation systems, and other infrastructure projects. Molding techniques help create customized parts, such as pipe junctions and transitions, ensuring systems are tailored to specific construction needs.

Medical and Laboratory Applications Specialized PVC molding is used to produce piping and components for medical and laboratory environments, where the durability and non-reactive nature of PVC are crucial. These applications include fluid transfer systems and laboratory containment piping.

Advantages of PVC Pipe Molding

Cost-Effectiveness: PVC is relatively inexpensive compared to other materials like metal or concrete. The molding processes are efficient, which helps keep production costs low.

Durability: PVC is highly resistant to corrosion, chemicals, and UV degradation, making it suitable for both indoor and outdoor applications.

Lightweight: PVC pipes are lightweight and easy to handle, reducing transportation and installation costs.

Ease of Fabrication: PVC can be easily molded into complex shapes, making it a versatile material for a wide range of applications.

Long Lifespan: PVC pipes can last for decades without significant degradation, making them a long-term solution for many infrastructure and industrial needs.

Challenges and Considerations

Environmental Impact: PVC is not biodegradable and can have environmental consequences if not disposed of properly. However, recycling programs for PVC materials are growing.

Temperature Sensitivity: While PVC is durable, it can become brittle at very low temperatures, which could limit its use in colder climates.

Installation Considerations: Some PVC pipes require special adhesives and jointing techniques to ensure a secure fit and prevent leakage.

Conclusion

PVC pipe molding techniques provide a versatile, cost-effective, and durable solution for creating a wide variety of pipe components used across different industries. From plumbing systems to industrial applications, PVC molded parts play an essential role in infrastructure and manufacturing. As molding technologies continue to evolve, the range of applications for PVC pipes and fittings will likely expand, contributing to more efficient, sustainable, and cost-effective solutions in various industries.