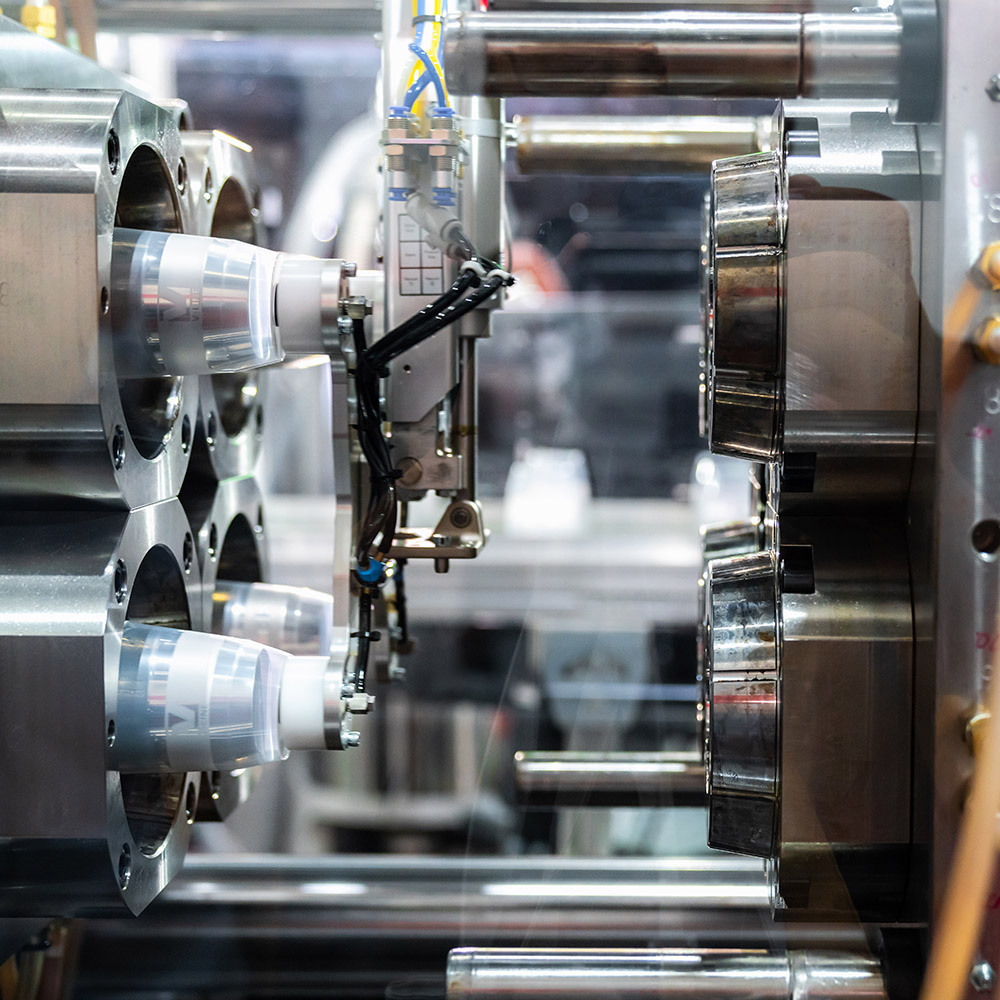

Injection molding is a widely used manufacturing process that involves injecting molten material (typically plastic) into a mold cavity to create parts with precise shapes and sizes. It has revolutionized the production of consumer goods due to its efficiency, cost-effectiveness, and ability to produce complex designs. Below are some key applications of injection molding in consumer goods:

1. Packaging

Injection molding is extensively used in the production of packaging materials such as bottles, containers, and caps. This process allows manufacturers to create intricate designs with tight tolerances, ensuring the packaging is both functional and visually appealing. Common products include:

Plastic bottles for beverages, household chemicals, and personal care products.

Caps and lids for containers, ensuring a secure and airtight seal.

Food packaging trays and containers, which benefit from the lightweight and durable nature of plastic.

2. Personal Care Products

The personal care industry relies on injection molding for producing a wide range of products. Injection molding provides the flexibility to create items with precise details and textures, which are essential in the cosmetics and hygiene sectors. Products include:

Shampoo bottles and cosmetic containers with customized shapes and designs.

Toothbrush handles and razor casings, which require ergonomic design and durability.

Cosmetic applicators, like compact cases and makeup containers.

3. Household Appliances and Tools

Consumer goods in the form of household appliances and tools often rely on injection-molded parts. Injection molding enables the mass production of durable, functional, and aesthetically appealing items. Examples include:

Vacuum cleaner parts, including housings, brushes, and wheels.

Power tool casings, such as for drills, saws, and grinders, which need both strength and precision.

Small appliance components, like microwave housings, coffee maker parts, and toasters.

4. Toys and Games

The toy industry benefits significantly from injection molding because of the ability to create small, detailed, and intricate designs in large quantities. Commonly injection-molded toy products include:

Action figures and dolls, which require complex details and multiple colors.

Building blocks like Lego, which need precision and high durability.

Game pieces for board games or interactive toys.

5. Automotive Accessories

Injection molding is also used in the production of consumer goods related to automotive accessories. These products benefit from the durability and precision of injection-molded parts. Common applications in automotive accessories include:

Interior components, such as dashboard parts, cup holders, and door panels.

Exterior parts, such as grilles, mirrors, and bumpers.

Storage solutions like organizer trays and compartments.

6. Electronics and Gadgets

Many consumer electronics and gadgets rely on injection molding for their external casings and internal components. Injection molding allows for the production of lightweight, durable, and intricately designed products. Common examples include:

Smartphone cases and tablet housings, which are designed to be slim yet durable.

Remote controls, where precision and ergonomics are essential.

Earphone and headphone casings, which require complex shapes and high-quality finishes.

7. Sports Equipment

Injection molding plays a vital role in the production of sports equipment due to its ability to produce lightweight, durable, and impact-resistant parts. Products in this category include:

Protective gear, such as knee pads, helmets, and shin guards.

Sports accessories, including water bottles, whistles, and grips for bats or racquets.

Footwear, particularly the production of soles and shoe components.

8. Furniture and Home Décor

Furniture and home décor items are increasingly using injection-molded components due to their versatility and the variety of materials available. Examples include:

Chairs, tables, and stools, which require both aesthetic appeal and structural integrity.

Storage containers and shelving units, which can be made from durable plastics.

Lighting fixtures like lampshades or lamp bases.

9. Healthcare Products

In the healthcare sector, injection molding is used to produce medical devices, equipment, and personal healthcare products that require high precision and reliability. These include:

Syringes and medical vials, which require high cleanliness and consistency.

Disposable medical products, such as pill bottles, inhalers, and diagnostic tools.

CPR masks and other emergency equipment, where precision and safety are critical.

10. Fashion Accessories

Fashion and accessories brands use injection molding to create intricate designs for various accessories. These are typically lightweight, durable, and customizable. Examples include:

Eyewear frames for glasses or sunglasses.

Watch components, such as cases and bands.

Belt buckles, jewelry, and other small fashion accessories.

Benefits of Injection Molding in Consumer Goods

Cost-Effectiveness: The ability to mass-produce goods at a lower cost makes injection molding ideal for consumer goods that require high-volume production.

Complex Designs: Injection molding can create highly complex shapes and fine details that may not be possible with other manufacturing techniques.

Material Variety: It offers flexibility in using a wide range of materials, including various plastics, metals, and composites.

Durability and Strength: Injection-molded parts tend to have superior strength and durability, making them ideal for both functional and aesthetic components.

Conclusion

Injection molding has become a cornerstone in the production of consumer goods, offering a wide range of applications across industries such as packaging, personal care, electronics, automotive, toys, and more. Its ability to produce high-quality, durable, and intricately designed products at scale makes it an indispensable technology for meeting the demands of modern manufacturing.