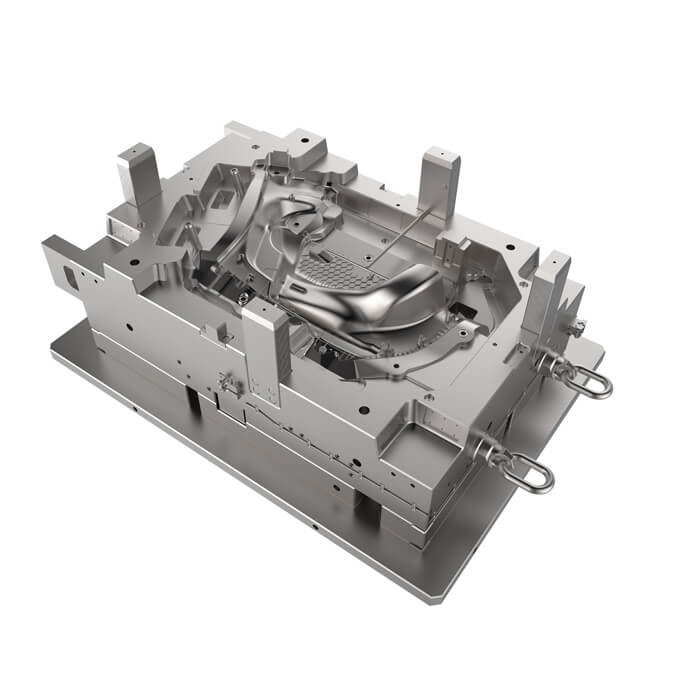

Steel Molds

Steel is a highly durable and strong material, making it a popular choice for high-volume automotive mold production. Steel molds are capable of withstanding the extreme pressures and high temperatures typically encountered in injection molding, ensuring the consistent quality of the parts over time. One of the main advantages of steel is its longevity; steel molds tend to last much longer than aluminum molds, which is critical for large-scale production where durability and extended use are necessary. Steel is also well-suited for complex and intricate mold designs, as it maintains its shape and precision even after extensive use. However, steel molds come with a higher upfront cost due to the more intensive machining required to produce them. They are also heavier, which can increase transportation and handling costs. Steel molds are also more prone to rusting if not properly maintained, requiring periodic maintenance to preserve their performance and quality.

Aluminum Molds

Aluminum molds are generally lighter, easier to machine, and less expensive to produce compared to steel molds, making them an attractive choice for prototyping and smaller production runs. One of the major advantages of aluminum is its superior thermal conductivity, which allows it to dissipate heat more quickly than steel. This results in faster cycle times and, therefore, increased productivity in the molding process. Aluminum molds are ideal when rapid turnarounds are needed, such as in the creation of prototypes or low-volume runs. However, aluminum molds are not as durable as steel and wear out more quickly under the high pressures and temperatures common in automotive molding. This makes aluminum a less suitable option for large-scale production, where mold longevity is essential. Additionally, aluminum molds can be more susceptible to deformation, which can affect the precision of molded parts over time. While aluminum offers cost savings in the short term, it is typically better suited for applications where speed and lower costs are more critical than long-term durability.