Predictive Maintenance for Automotive Molds

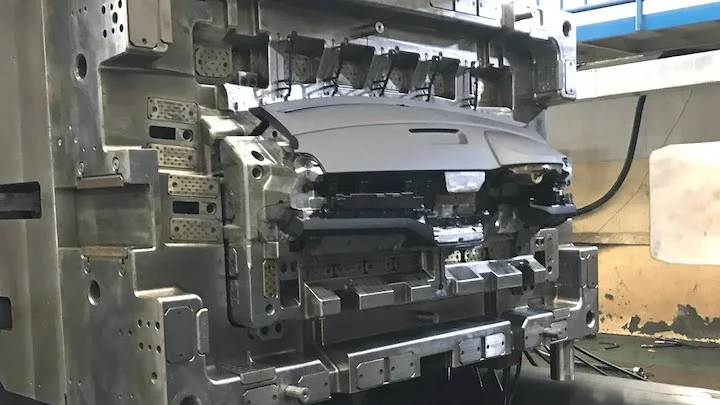

Predictive Maintenance for Automotive Molds Predictive maintenance (PdM) is transforming the automotive molding industry by leveraging AI, IoT sensors, and data analytics to anticipate mold failures before they occur. This proactive approach minimizes downtime, reduces repair costs, and extends mold lifespan, ensuring continuous and high-quality production of automotive components. Key Benefits of Predictive Maintenance in […]

Predictive Maintenance for Automotive Molds Read More »