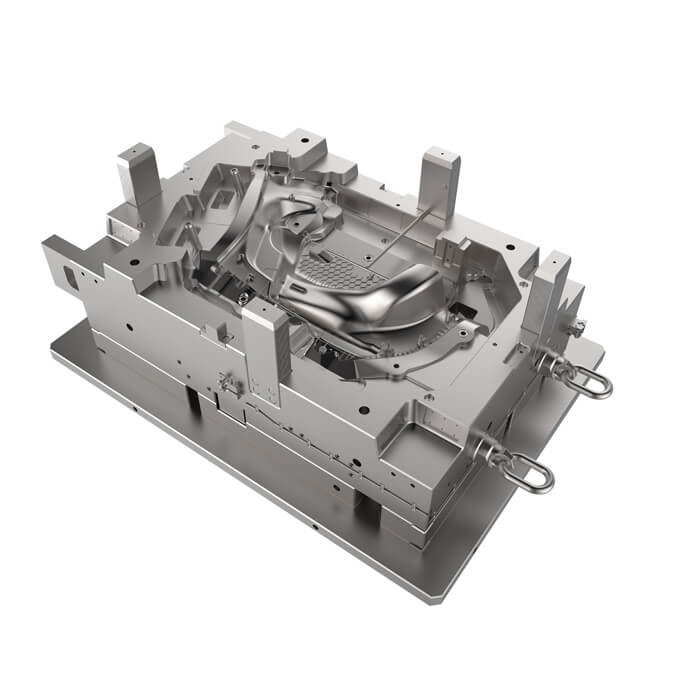

Tooling for Automotive Molds

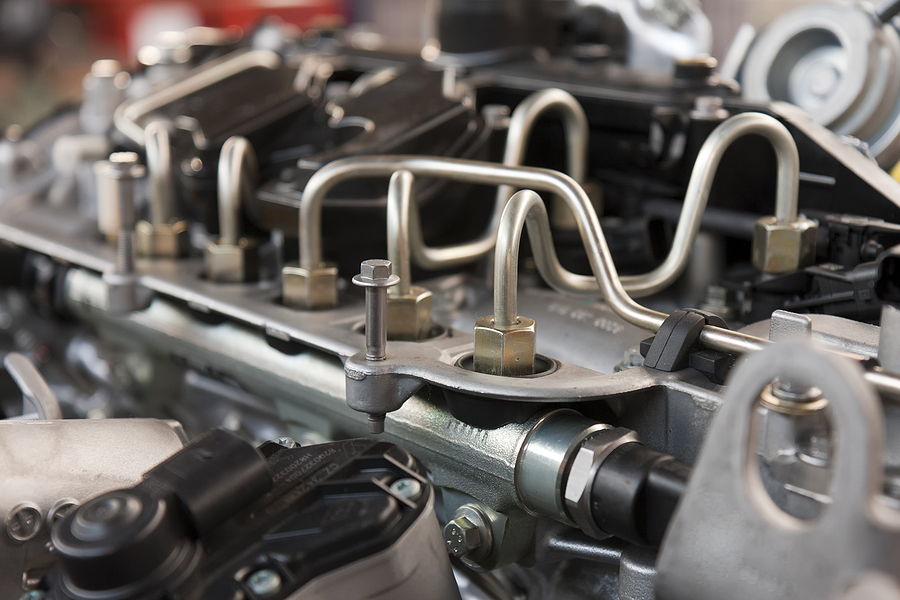

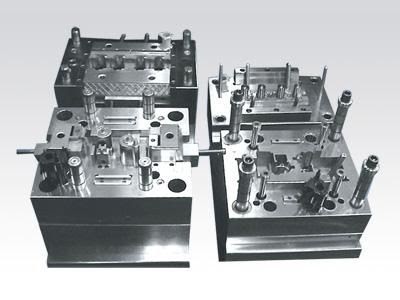

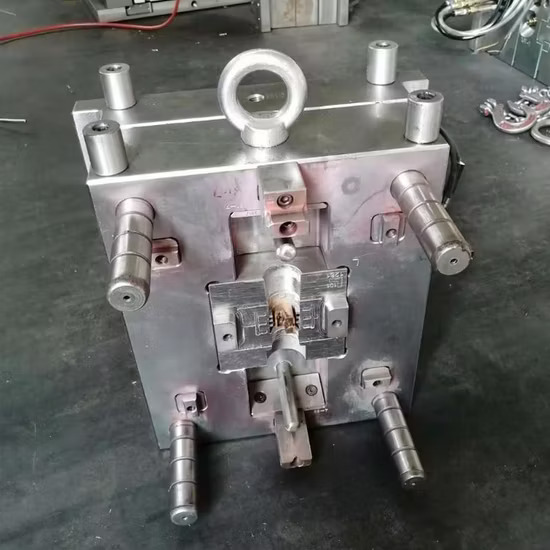

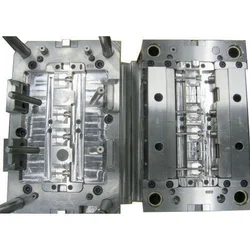

Tooling for automotive molds is a critical component in the manufacturing process of vehicle parts, ensuring precision, efficiency, and durability. Automotive molds are used to produce various components, including interior panels, exterior body parts, and functional systems, requiring them to meet stringent industry standards. The tooling process involves a series of specialized steps to create […]

Tooling for Automotive Molds Read More »