Predictive Maintenance for Injection Molds

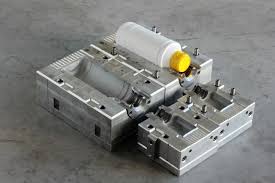

Predictive Maintenance for Injection Molds Predictive maintenance (PdM) is revolutionizing injection mold management by using IoT sensors, AI-driven analytics, and machine learning to predict potential failures before they happen. This approach minimizes unplanned downtime, reduces maintenance costs, and ensures consistent part quality, making it essential for high-volume manufacturing industries like automotive, aerospace, medical, and consumer […]

Predictive Maintenance for Injection Molds Read More »