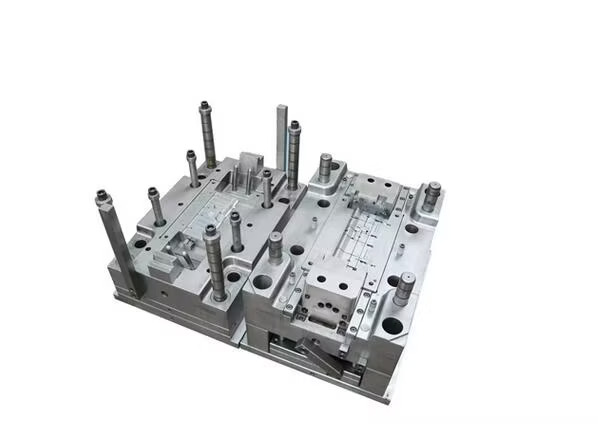

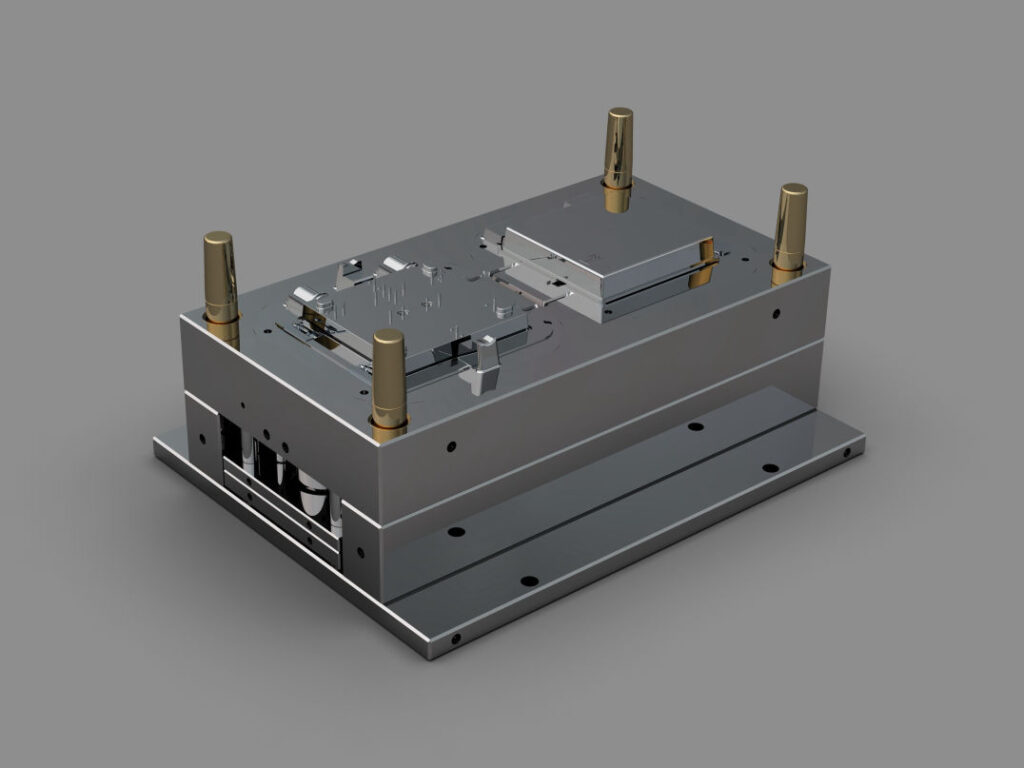

Thin-Wall Injection Molding Techniques

ing Techniques Thin-wall injection molding is a specialized manufacturing process used to produce lightweight, high-strength plastic components with extremely thin walls. This technique is widely applied in industries such as electronics, automotive, and packaging, where reducing material usage and achieving precision are critical. Mastering thin-wall injection molding requires advanced techniques, specialized equipment, and a deep […]

Thin-Wall Injection Molding Techniques Read More »