How Automation is Transforming PVC Molding

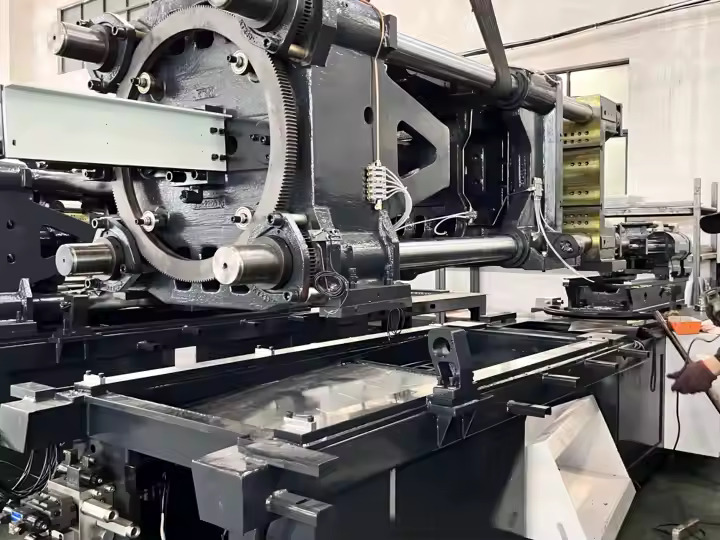

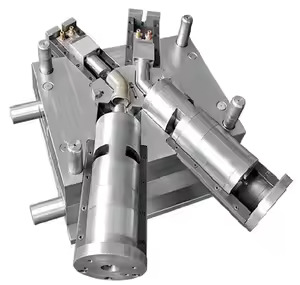

Automation is reshaping the landscape of PVC molding, making the process faster, more precise, and cost-effective while addressing the challenges associated with molding polyvinyl chloride (PVC). This transformation is driven by the integration of robotics, advanced machinery, and smart technologies, which together enhance production capabilities and product quality. Streamlining Production ProcessesAutomation reduces cycle times and […]

How Automation is Transforming PVC Molding Read More »