Design for Manufacturability (DFM) is an engineering practice that emphasizes designing products in a way that makes them easier and more cost-effective to manufacture. In the context of automotive molding, DFM plays a crucial role in optimizing the design and production process, ensuring high-quality parts while minimizing manufacturing difficulties and costs.

Key Principles of DFM in Automotive Molding:

Simplified Geometry

One of the key goals of DFM is to reduce the complexity of part geometry. In automotive molding, intricate shapes may be difficult or costly to manufacture, especially with processes like injection molding, die casting, or compression molding. By simplifying the geometry, manufacturers can streamline the molding process, reduce cycle times, and minimize defects. This could involve using less detailed surfaces, fewer undercuts, and avoiding unnecessary features that complicate mold design.Material Selection

Choosing the right material is vital in automotive molding, as it impacts part performance, manufacturability, and cost. For DFM, materials should be selected based on factors like ease of molding, compatibility with the molding process, mechanical properties, and long-term durability. Materials that have consistent flow characteristics and are easily moldable can reduce the likelihood of defects such as warping, voids, or improper filling.Mold Design Optimization

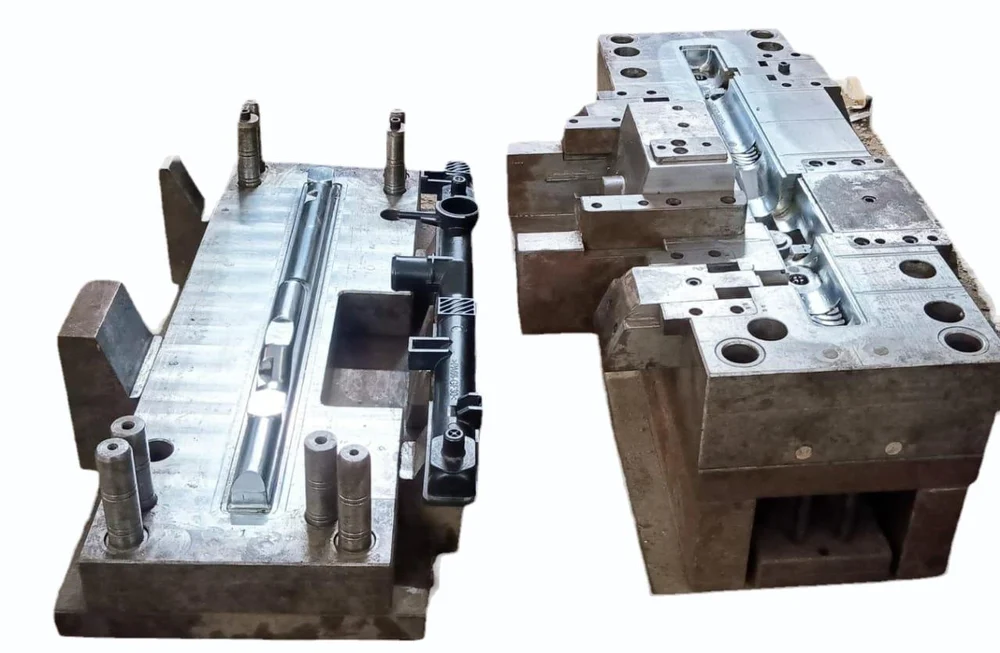

A well-designed mold is crucial to the success of automotive molding. DFM principles encourage the optimization of mold design by considering factors like parting lines, draft angles, and mold vents. Proper draft angles make it easier to eject the part from the mold, reducing the chances of part damage. Mold vents allow air and gases to escape, preventing defects like air traps and burn marks. In addition, ensuring proper cooling channel design helps in reducing cycle times and preventing warping.Tolerance and Fit

Tight tolerances in automotive parts can increase manufacturing complexity, particularly in molding processes. DFM advocates for a balanced approach to part tolerances, ensuring that they are within the necessary limits but not excessively tight. By designing parts with appropriate tolerances, manufacturers can reduce the need for costly secondary operations like grinding or machining. Additionally, minimizing tolerance variations can lead to better consistency and less waste.Minimizing Secondary Operations

In automotive molding, it is ideal to design parts that require minimal post-molding processes. Secondary operations, such as trimming, machining, or assembly, add time and cost to the production process. DFM encourages designing parts in such a way that they can be molded close to the final shape, reducing the need for these additional steps. This not only lowers the overall cost but also improves the speed and efficiency of production.Designing for Assembly (DFA)

Automotive molding parts often need to be assembled into larger systems. DFM integrates Design for Assembly (DFA) principles to ensure that molded components are designed to be easily assembled with minimal handling, reducing labor costs and assembly time. This can involve features like snap-fits, interlocking parts, or the use of self-locating fasteners.Design for Sustainability

As sustainability becomes increasingly important in the automotive industry, DFM in molding also incorporates considerations for reducing environmental impact. This includes using recyclable materials, minimizing waste in the production process, and optimizing the design to reduce the energy required during manufacturing. By focusing on sustainability, manufacturers can meet regulatory standards and appeal to environmentally-conscious consumers.

Benefits of DFM in Automotive Molding:

Cost Reduction: By simplifying part design and minimizing the need for secondary processes, DFM helps to reduce production costs, making the overall manufacturing process more affordable.

Improved Quality: By focusing on manufacturability from the design phase, DFM minimizes the risk of defects and ensures that parts meet the required specifications more consistently.

Faster Time to Market: Streamlined designs and optimized production processes result in shorter lead times, enabling automotive manufacturers to bring products to market faster and respond more quickly to consumer demands.

Enhanced Sustainability: DFM practices can help reduce waste, improve material usage, and lower energy consumption, contributing to more sustainable automotive production.

Conclusion:

Design for Manufacturability (DFM) is an essential approach in automotive molding that helps manufacturers produce high-quality, cost-effective parts with minimal complexity. By considering factors such as material selection, part geometry, mold design, tolerance management, and sustainability, automotive companies can achieve better manufacturing efficiency, reduce production costs, and ensure quicker product launches. Integrating DFM principles into the early stages of the design process is key to optimizing the entire manufacturing lifecycle and ensuring that automotive parts meet both performance and cost targets.