1. Introduction

Die and mould bases are essential components in manufacturing processes such as metal stamping, plastic injection moulding, and die casting. These bases serve as the structural foundation that holds and supports the die or mould inserts during operation. As these components endure significant mechanical loads, thermal stresses, and dynamic forces during cycles, stress analysis is vital to ensure structural integrity, performance, and longevity.

2. Importance of Stress Analysis in Die and Mould Bases

Safety: Prevents catastrophic failures that could result in equipment damage or operator injury.

Durability: Ensures that components withstand repeated loading without fatigue.

Performance: Maintains dimensional accuracy and quality of manufactured parts.

Cost-Efficiency: Reduces maintenance, repair, and downtime through optimized design.

3. Types of Stresses in Die and Mould Bases

Mechanical Stresses:

Compressive and Tensile Stresses: Arise due to clamping forces and part ejection.

Bending Stresses: Occur in large bases due to uneven load distribution.

Shear Stresses: Develop at contact interfaces during material flow or part ejection.

Thermal Stresses:

Result from temperature gradients, especially in plastic injection moulding and die casting.

Residual Stresses:

Introduced during manufacturing processes such as welding or machining.

Fatigue Stresses:

Caused by repeated cyclic loading and unloading during production cycles.

4. Stress Analysis Methods

4.1 Analytical Methods

Useful for simple geometries and preliminary calculations.

Based on classical mechanics and strength of materials equations (e.g., beam theory, plate theory).

4.2 Finite Element Analysis (FEA)

Most widely used and accurate method.

Allows simulation of complex geometries, loads, and boundary conditions.

Helps identify high-stress concentration zones and potential failure points.

4.3 Experimental Methods

Strain Gauges: Measure actual strain under operating conditions.

Photoelasticity: Visualizes stress distribution using birefringent materials.

Digital Image Correlation (DIC): Non-contact method to measure surface strain.

5. Key Factors Affecting Stress in Die and Mould Bases

Material Properties: Strength, hardness, thermal conductivity, and fatigue resistance.

Geometry and Design: Thickness, fillets, ribs, and support structures.

Manufacturing Tolerances: Misalignment can induce stress concentrations.

Operating Conditions: Clamping force, injection pressure, thermal cycles, and cycle frequency.

6. Design Considerations for Stress Minimization

Use of high-strength tool steels or pre-hardened alloy steels for the base.

Incorporation of fillets at corners to reduce stress concentrations.

Adequate cooling channel design to minimize thermal gradients.

Proper support pillar placement to distribute load evenly.

Avoidance of sharp internal features and overhangs.

7. Case Studies and Applications

Plastic Injection Moulds: Thermal fatigue and clamp force stresses dominate. Stress analysis ensures proper cooling and avoids warping.

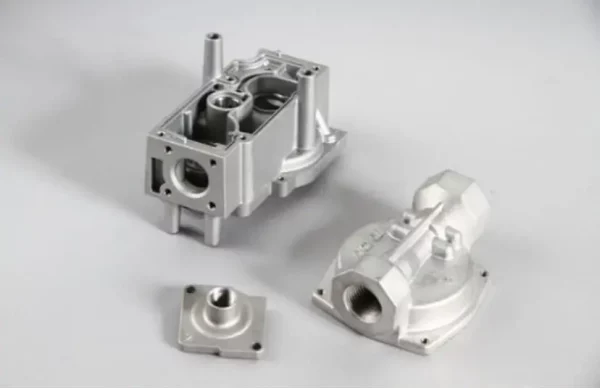

Die Casting Dies: Subjected to high temperatures and pressures; analysis focuses on thermal and mechanical fatigue.

Sheet Metal Dies: Primarily experience impact and shear stresses; focus on dynamic stress response.

8. Conclusion

Stress analysis of die and mould bases is crucial for the reliability and efficiency of forming and moulding operations. Through a combination of analytical tools, numerical simulations, and experimental validation, engineers can design robust mould bases that perform optimally under demanding industrial conditions.

9. References (for Academic Use)

Shigley, J.E., “Mechanical Engineering Design.”

Altan, T., “Metal Forming: Fundamentals and Applications.”

ABAQUS, ANSYS Documentation – FEA Simulation for Tooling.

Journals: International Journal of Advanced Manufacturing Technology, Journal of Materials Processing Technology.