Sure! Here’s a step-by-step explanation of the Extrusion Blow Moulding (EBM) process, which is commonly used to manufacture hollow plastic parts like bottles and containers.

Extrusion Blow Moulding Process: Step-by-Step

1. Plastic Melting (Extrusion)

Raw material, typically in the form of plastic pellets (e.g., HDPE, PP), is fed into a hopper.

The pellets are moved through a heated barrel by a rotating screw.

As the plastic moves along the screw, it is melted by friction and external heaters to form a viscous molten polymer.

2. Parison Formation

The molten plastic is pushed through a die head, forming a hollow tube of plastic called a parison.

The parison is extruded vertically between two halves of an open mold.

3. Mold Closing

The mold halves close around the parison, sealing the bottom end and preparing for inflation.

The mold contains the cavity shape of the final product.

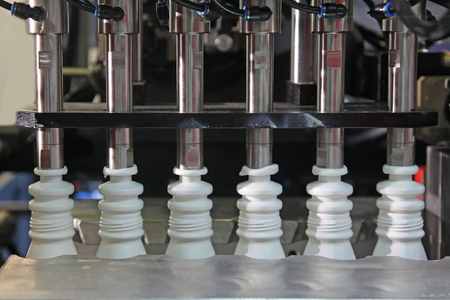

4. Inflation (Blow Moulding)

A blow pin or needle is inserted into the open end of the parison.

Compressed air is blown into the parison, causing the molten plastic to expand and conform to the shape of the mold cavity.

5. Cooling

The molded plastic part is cooled within the mold, either through water channels in the mold or ambient air.

Cooling solidifies the plastic, allowing it to retain the shape of the mold.

6. Mold Opening and Ejection

Once sufficiently cooled and solidified, the mold opens.

The finished product (e.g., bottle or container) is ejected from the mold.

7. Trimming and Finishing

Excess plastic (flash) from the top, bottom, or along mold lines is trimmed off.

Additional processes like printing, labeling, or quality checks may follow.

Applications

Extrusion Blow Moulding is widely used to manufacture:

Plastic bottles (e.g., milk jugs, shampoo bottles)

Fuel tanks

Automotive ducts

Containers for household and industrial use

Advantages

Economical for high-volume production

Suitable for a wide range of plastics

Capable of producing complex, hollow shapes

Limitations

Limited precision compared to injection molding

Wall thickness may vary

Not ideal for small, intricate parts