Fire-retardant PVC (polyvinyl chloride) is an important material used in injection molding when a product or component needs to meet specific fire safety standards. It’s commonly used in a variety of industries such as automotive, construction, electronics, and more, where there is a need for materials to resist ignition or slow the spread of fire. The addition of fire-retardant agents to PVC enhances its ability to meet fire resistance requirements while still maintaining the properties of regular PVC, such as flexibility, durability, and ease of molding.

Key Characteristics of Fire-Retardant PVC in Molding:

1. Fire Resistance

- Fire-retardant PVC is designed to self-extinguish when exposed to flames, helping to prevent the spread of fire. This is particularly important in applications where human safety, property protection, or electrical safety are critical.

- The fire-retardant properties are achieved by adding halogen-based or non-halogen-based fire retardants to the PVC compound. These additives either release gases that inhibit combustion or form a protective char layer that insulates the material from the fire.

2. Material Composition

- Halogen-based retardants (e.g., bromine, chlorine) are commonly used in PVC to enhance its fire resistance. These compounds are effective at lowering the flammability of the material but can release harmful byproducts like hydrogen chloride when burned.

- Non-halogen-based retardants, such as phosphates or borates, are often preferred in applications where toxicity concerns are paramount. These retardants are increasingly popular due to their environmentally friendly characteristics.

3. Heat Resistance

- In addition to fire resistance, fire-retardant PVC often has enhanced heat resistance. This means it can withstand higher temperatures without losing its structural integrity, which is crucial in environments subject to heat exposure.

4. Flame Retardant Standards

- Fire-retardant PVC is often designed to meet specific fire safety standards, such as UL 94 (a standard for flammability of plastic materials) or IEC 60332 (a standard for cable fire safety in electronics). These standards help ensure that the material provides adequate fire protection.

- PVC that meets these standards is typically classified in terms of its flame-retardant rating, such as V-0, V-1, or V-2 under UL 94, with V-0 being the highest rating (self-extinguishing within 10 seconds and no flaming drips).

Applications of Fire-Retardant PVC in Injection Molding:

1. Automotive Industry

- Wiring Insulation and Cable Jackets: Fire-retardant PVC is commonly used in automotive electrical wiring and cable jackets to prevent fires in case of short circuits or accidents.

- Interior Components: Parts like dashboards, door panels, and seat components are often made with fire-retardant PVC to ensure safety in the event of an accident or fire inside the vehicle.

2. Electrical and Electronics

- Conduit and Cable Insulation: PVC is widely used for electrical conduit and cable insulation due to its excellent dielectric properties and the ability to meet fire-resistance requirements. The addition of fire retardants makes it safer for use in buildings, industrial equipment, and electronic devices.

- Circuit Board Components: Fire-retardant PVC may also be used for the housing of circuit boards and other components where flame resistance is necessary.

3. Construction and Building Materials

- Pipes and Fittings: In construction, fire-retardant PVC pipes are used for plumbing and electrical conduit systems to prevent the spread of fire through pipes.

- Wall Panels and Flooring: Fire-retardant PVC panels are used for interior cladding, wall panels, and flooring in commercial and residential buildings where fire safety regulations are critical.

- Cables: Fire-retardant PVC cables are used in wiring systems in buildings, especially in high-rise buildings, ensuring that electrical fires are contained within specific zones.

4. Consumer Goods

- Home Appliances: Many home appliances, such as air conditioners, refrigerators, and washing machines, use fire-retardant PVC for their external parts or internal insulation materials to prevent fire hazards.

- Toys: In certain applications, fire-retardant PVC is used to ensure safety standards are met in children’s toys and devices that could be exposed to heat or flames.

Benefits of Using Fire-Retardant PVC in Injection Molding:

1. Improved Safety

- Fire-retardant PVC significantly enhances the safety of products, reducing the risk of fire hazards in environments where heat and electrical malfunctions are possible.

2. Cost-Effective

- Compared to other materials that offer fire resistance (like metals or specialized coatings), fire-retardant PVC is relatively inexpensive. It combines excellent fire-resistance properties with the affordability of standard PVC, making it a cost-effective option for mass production.

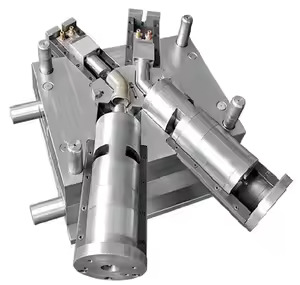

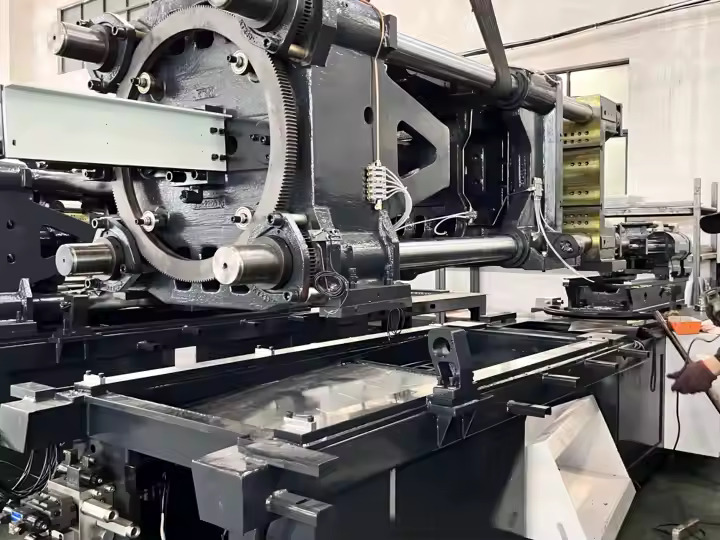

3. Moldability

- PVC is one of the most versatile materials in injection molding. The addition of fire retardants does not significantly impact its ability to be molded into complex shapes, making it ideal for creating intricate components such as electrical connectors, enclosures, and cable jackets.

- The material can be easily processed, which enables manufacturers to produce high-quality parts with high precision and minimal waste.

4. Durability

- Fire-retardant PVC retains the inherent benefits of PVC, including resistance to chemicals, weather, and UV radiation. This makes it durable for long-term use in a variety of demanding environments.

5. Environmental and Regulatory Compliance

- Non-halogenated fire-retardant PVC options help companies meet stricter environmental regulations that limit the use of hazardous chemicals. This makes it an attractive option for industries looking to meet environmental sustainability standards.