Heat resistance is a critical attribute in automotive molds due to the demanding thermal conditions encountered during both the molding process and the application of the final products. Automotive molds are subjected to high temperatures from molten materials such as plastics, rubbers, or metals during production, necessitating the use of materials that can withstand extreme heat without warping, cracking, or degrading. Tool steels, high-performance alloys, and ceramics are commonly used for molds due to their excellent thermal stability, wear resistance, and mechanical strength.

The automotive industry requires components with high heat resistance, particularly for parts near engines, exhaust systems, or areas exposed to prolonged sunlight. To meet these requirements, the molds must be designed to produce parts with consistent mechanical properties, precise dimensions, and surface finishes that remain unaffected under extreme thermal conditions. This often involves using advanced heat treatment processes for the mold materials, such as annealing, nitriding, or surface coatings, to enhance thermal resistance and durability.

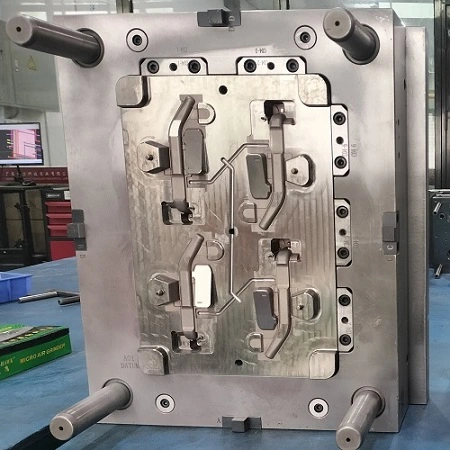

Thermal management is a key consideration in mold design. Cooling systems, such as optimized channels for liquid cooling or heat pipes, are integrated into molds to control temperature fluctuations during production. Effective cooling not only prevents overheating and thermal fatigue but also reduces cycle times, improving manufacturing efficiency. Modern simulation tools enable engineers to model thermal behavior during the design phase, allowing them to predict and mitigate potential issues related to heat stress.

By ensuring high heat resistance in automotive molds, manufacturers can produce reliable, high-quality components that meet the stringent safety, durability, and performance standards of the automotive industry, even in the most demanding thermal environments.