Origins of Plastic Injection Molding

The origins of plastic injection molding trace back to the late 19th century, when inventors began exploring ways to shape plastics into functional items. In 1872, American inventor John Wesley Hyatt, along with his brother Isaiah, developed the first injection molding machine. This early machine was rudimentary, utilizing a plunger system to inject hot plastic into a mold to create basic items like buttons and combs. Despite its simplicity, this invention laid the foundation for modern plastic injection molding, sparking interest in developing the process further.

Technological Advancements in the 20th Century

Through the early 20th century, advances in materials and machinery led to significant improvements in injection molding. During this time, the industry shifted from using celluloid, the first plastic used in molding, to newer, more durable materials such as Bakelite. By the 1930s and 1940s, advancements in engineering and the introduction of thermoplastics transformed the industry. The plastic injection molding process became more efficient, allowing for quicker production cycles and the creation of increasingly complex parts. World War II further accelerated innovation as demand for plastic products, especially for military applications, surged, creating a need for rapid and large-scale production.

Post-War Expansion and Diverse Applications

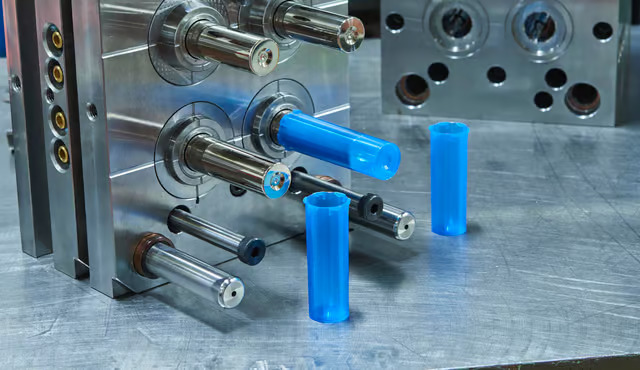

After World War II, plastic injection molding saw unprecedented growth as industries worldwide sought cost-effective ways to manufacture a variety of products. The versatility of plastic and the efficiency of injection molding led to widespread adoption across automotive, medical, consumer goods, and electronics industries. During the 1950s and 1960s, new developments in machinery, such as hydraulic systems and improved mold designs, made it possible to produce highly detailed and consistent parts. This period marked a significant expansion in both the capabilities and applications of injection molding, establishing it as an essential manufacturing process.

Modern Injection Molding and Future Innovations

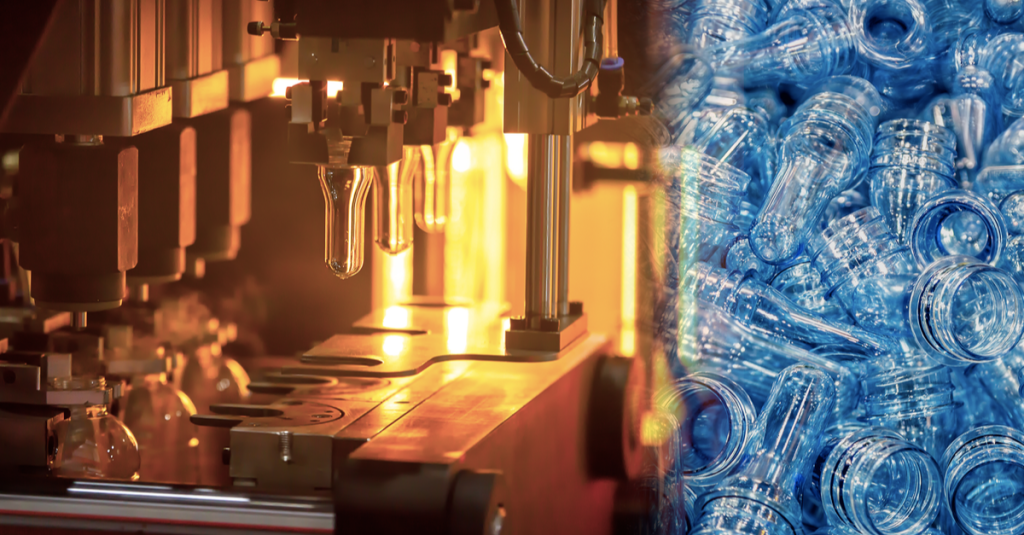

Today, plastic injection molding remains one of the most popular and efficient methods for mass production, with technological advancements continuing to push the process forward. Innovations like computer-aided design (CAD), automation, and 3D printing are enhancing mold design, precision, and production speed. Additionally, the development of more sustainable materials, including biodegradable plastics, aims to address environmental concerns. As industries adopt smart manufacturing practices, injection molding is evolving to be even more adaptable, cost-effective, and eco-friendly, ensuring its relevance in the future of manufacturing.