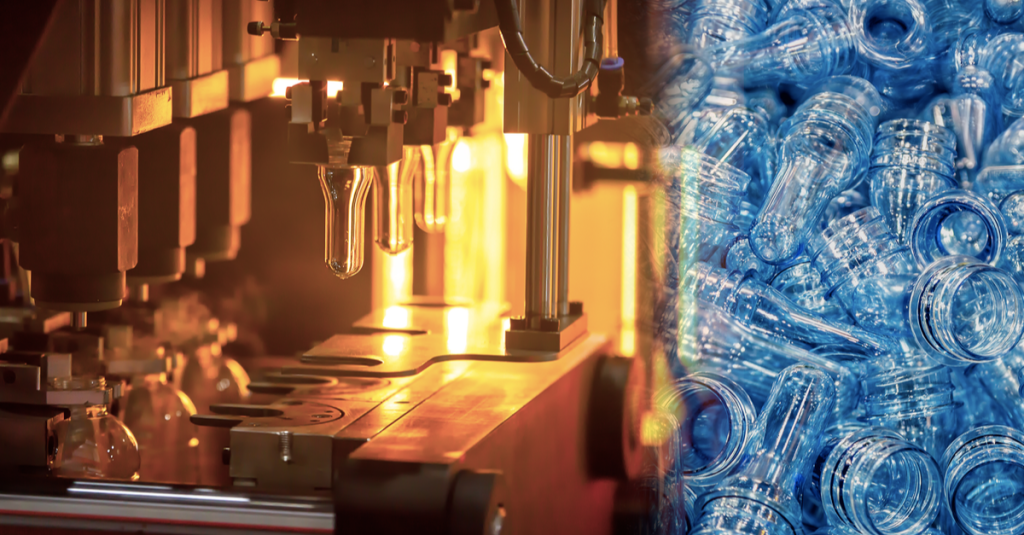

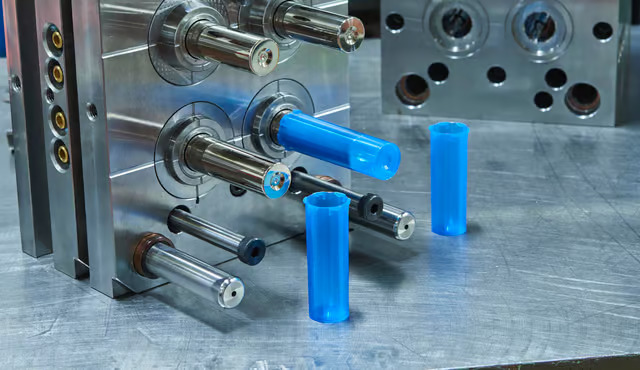

Injection molding is a widely used manufacturing process for creating parts by injecting molten material into a mold. This technique is primarily utilized for producing plastic components, though it is also applicable to metals, ceramics, and glass. The process begins with the heating of raw material, which is then forced under pressure into a custom-designed mold cavity. After cooling and solidifying, the molded part is ejected, ready for finishing or assembly. Injection molding is celebrated for its ability to produce complex shapes with high precision, repeatability, and efficiency.

Product safety standards are critical frameworks designed to ensure the safety, reliability, and functionality of goods for consumers and industries. These standards, often established by regulatory bodies, industry organizations, or international bodies like ISO (International Organization for Standardization) and ASTM (American Society for Testing and Materials), outline essential criteria for design, manufacturing, testing, and labeling. Compliance with these standards is often legally mandated and serves to protect users from hazards like electrical shocks, chemical exposure, mechanical failures, or biological risks.

For products created using injection molding, adherence to safety standards is essential to maintain material integrity, avoid defects, and ensure the final product meets its intended purpose without posing harm. For instance, in the medical device industry, ISO 13485 governs the quality management systems required for medical-grade injection-molded products. Similarly, toy manufacturing often requires compliance with ASTM F963 to ensure child safety. Meeting these standards not only builds consumer trust but also mitigates legal risks and enhances a company’s reputation. Regular testing, inspections, and certifications are integral to maintaining compliance and ensuring that products consistently meet or exceed safety expectations.