As the global shift toward electric vehicles (EVs) accelerates, manufacturers are seeking innovative, scalable, and cost-effective production methods to meet the growing demand. One area seeing rapid advancement is the manufacturing of battery components—especially through injection molding. This process, traditionally used in the plastics and automotive industries, is now a key enabler of lightweight, high-performance, and precision-engineered parts for EV battery systems.

Why Injection Molding?

Injection molding offers a range of advantages that make it ideal for electric vehicle battery components:

High Precision and Repeatability

Tight tolerances and complex geometries are critical for battery pack design. Injection molding ensures consistent part quality across high volumes.Lightweight Materials

Thermoplastics and advanced polymer composites help reduce overall vehicle weight, improving energy efficiency and driving range.Scalability

Once the mold is created, thousands to millions of identical components can be produced at a low per-unit cost.Design Flexibility

Engineers can integrate multiple functions (e.g., insulation, fluid channels, structural supports) into a single molded part.

Key Battery Components Manufactured via Injection Molding

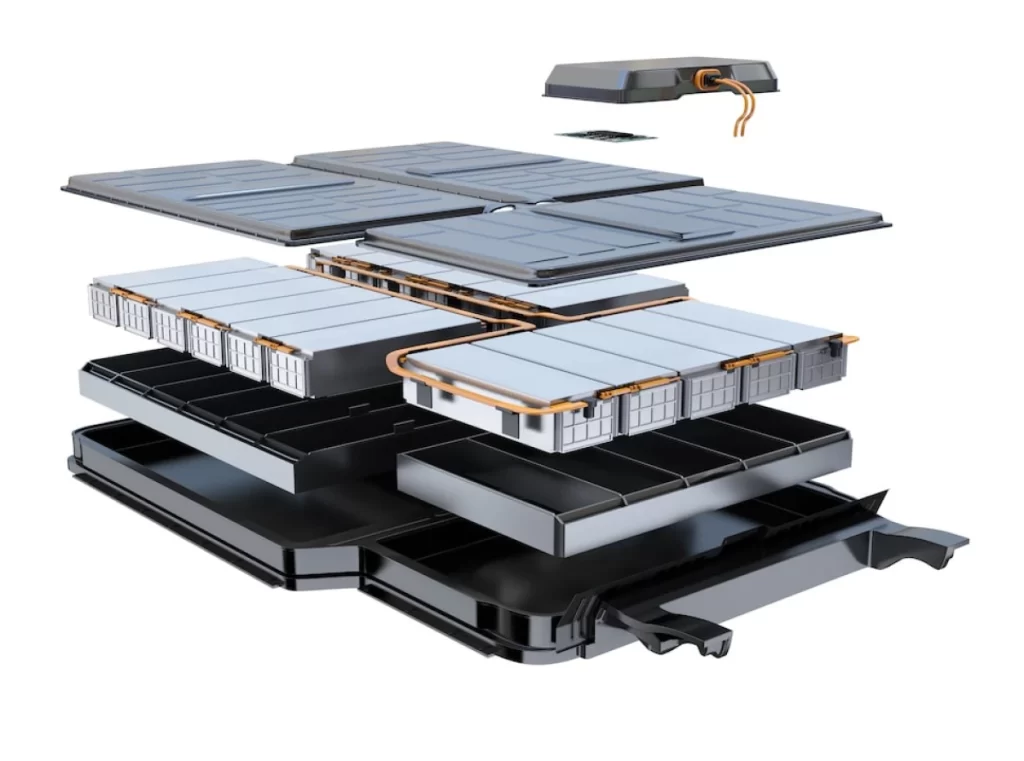

Battery Module Housings

These casings protect internal cells and provide structural support. They are often made from flame-retardant thermoplastics to ensure thermal and electrical safety.Cell Spacers and Holders

Injection-molded spacers maintain safe distances between individual battery cells, preventing short circuits and enhancing heat dissipation.Thermal Management Components

Elements like cooling plates or air ducts can be integrated into the battery pack using injection molding techniques.Electrical Insulators

Plastic insulators prevent electrical arcing and improve battery safety, especially in high-voltage systems.Seals and Gaskets

Custom-molded elastomeric components ensure water and dust ingress protection (IP ratings) for battery enclosures.

Materials Used in EV Battery Injection Molding

Polycarbonate (PC)

Offers excellent impact resistance and electrical insulation.Polyamide (Nylon) with Glass Fiber

Provides strength and thermal stability for structural parts.PBT (Polybutylene Terephthalate)

Commonly used for connectors and insulators due to its dimensional stability and flame retardance.Thermoplastic Elastomers (TPE)

Used in seals and vibration-dampening parts.Liquid Silicone Rubber (LSR)

Ideal for high-precision gaskets and seals with excellent thermal properties.

Benefits for EV Manufacturers

Reduced Production Costs

Fewer parts, less assembly time, and lower waste contribute to overall cost savings.Improved Safety and Compliance

Flame-retardant and non-conductive materials help meet strict safety standards (e.g., UL 94, ISO 26262).Shorter Time-to-Market

Rapid tooling and prototyping methods enable faster design iterations and product launches.Sustainability

Injection molding supports the use of recyclable polymers and closed-loop material systems, aligning with EV makers’ sustainability goals.

Challenges and Innovations

While injection molding brings numerous benefits, challenges such as mold wear from abrasive fillers, material outgassing, and high tooling costs for initial development must be addressed. Industry players are actively innovating with:

Advanced mold coatings and materials

Simulation software for design validation

Hybrid molding techniques (e.g., insert molding with metal or composite inserts)

Conclusion

Injection molding is playing a pivotal role in the evolution of electric vehicle battery technology. Its ability to produce complex, lightweight, and high-performance components makes it a cornerstone of modern EV manufacturing strategies. As materials and tooling technologies continue to advance, injection molding will further unlock opportunities for safer, more efficient, and more sustainable electric mobility solutions.