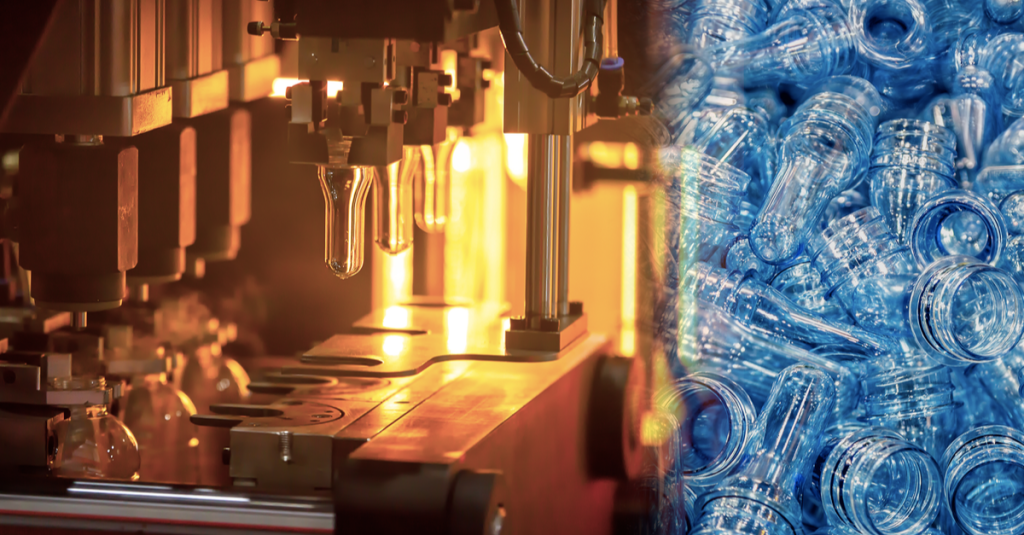

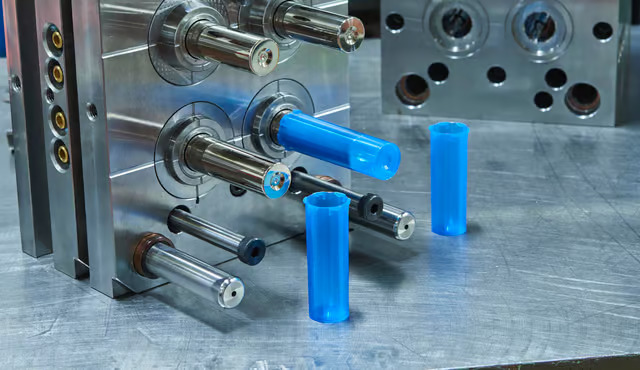

Injection molding is a highly precise manufacturing process widely used in the medical industry to produce high-quality, consistent, and sterile components. It involves melting thermoplastic or thermosetting polymers and injecting them into a mold to create parts with complex geometries. This technique is favored in medical applications due to its ability to produce intricate parts with tight tolerances, ensuring that components meet stringent regulatory standards. Common materials used include polycarbonate, polypropylene, and medical-grade silicone, which offer biocompatibility, durability, and resistance to sterilization processes such as autoclaving or gamma irradiation.

The medical industry benefits significantly from injection molding for the production of items like surgical instruments, diagnostic devices, syringes, implants, and components for medical equipment. The process allows for high-volume production while maintaining consistency in each unit, a critical requirement for medical-grade products. Additionally, the ability to use multi-cavity molds reduces costs and increases efficiency, making it ideal for both disposable and reusable medical components.

Sterility and precision are paramount in medical applications, and injection molding excels in this aspect. Cleanroom molding is often employed to prevent contamination during the manufacturing process, adhering to ISO 13485 and other regulatory requirements. Moreover, advances in micro-molding technology enable the production of ultra-small parts used in minimally invasive surgical devices and advanced diagnostic equipment.

Customization is another advantage of injection molding in medical applications. It allows for the creation of tailored designs to fit specific patient needs, such as custom implants or prosthetics. With the integration of modern technologies like 3D printing for mold prototyping and computer-aided design (CAD), manufacturers can streamline the development cycle and reduce time to market. This combination of precision, efficiency, and adaptability ensures that injection molding remains an essential manufacturing process in the evolving field of medical technology.