Injection Molding for Military and Defense Applications

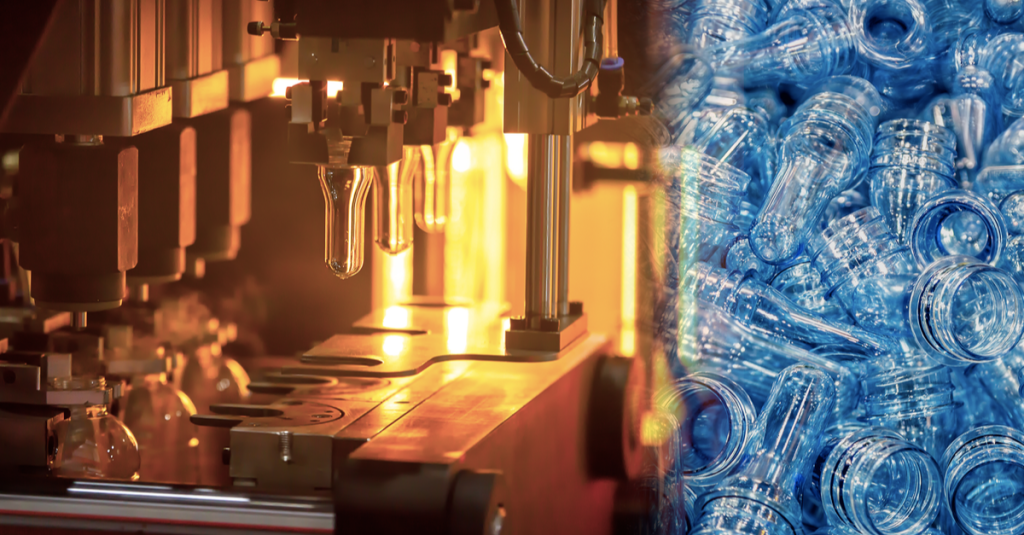

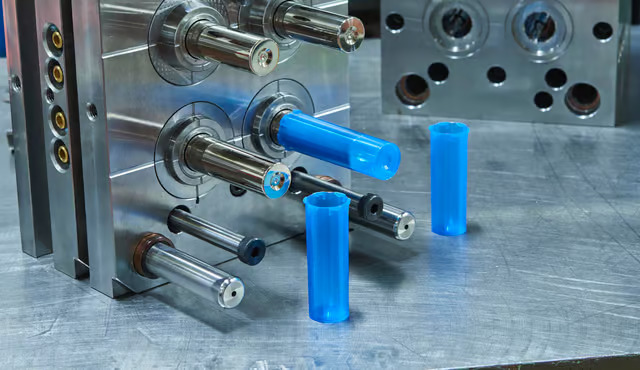

Injection molding plays a crucial role in military and defense manufacturing, offering high-precision, durable, and cost-effective solutions for mission-critical components. With advancements in high-performance polymers, composites, and specialized molding techniques, injection molding provides the military sector with lightweight, rugged, and reliable parts that meet stringent defense standards.

Key Advantages of Injection Molding in Defense

- High Strength & Durability – Molded components withstand extreme temperatures, impact, and chemical exposure.

- Lightweight Design – Advanced polymer-based materials reduce weight without compromising strength, enhancing mobility.

- Precision & Consistency – CNC-controlled molding ensures tight tolerances and repeatability for critical applications.

- Cost-Effective Mass Production – Molding allows for high-volume, low-cost production of complex parts.

- Customizable & Versatile – Supports special coatings, reinforcements, and integrated electronics for advanced military applications.

Common Military & Defense Applications

🔹 Weapons & Ammunition Components – Polymer-based firearm frames, grips, holsters, and magazine casings.

🔹 Protective Gear & Equipment – Lightweight helmet shells, ballistic armor, visors, and tactical accessories.

🔹 Communication & Electronics – Ruggedized housings for radios, drones, GPS systems, and night-vision devices.

🔹 Vehicle & Aerospace Parts – Impact-resistant dashboards, handles, brackets, and structural reinforcements.

🔹 Medical & Field Equipment – Portable medical kits, cases, and sterile medical device housings.