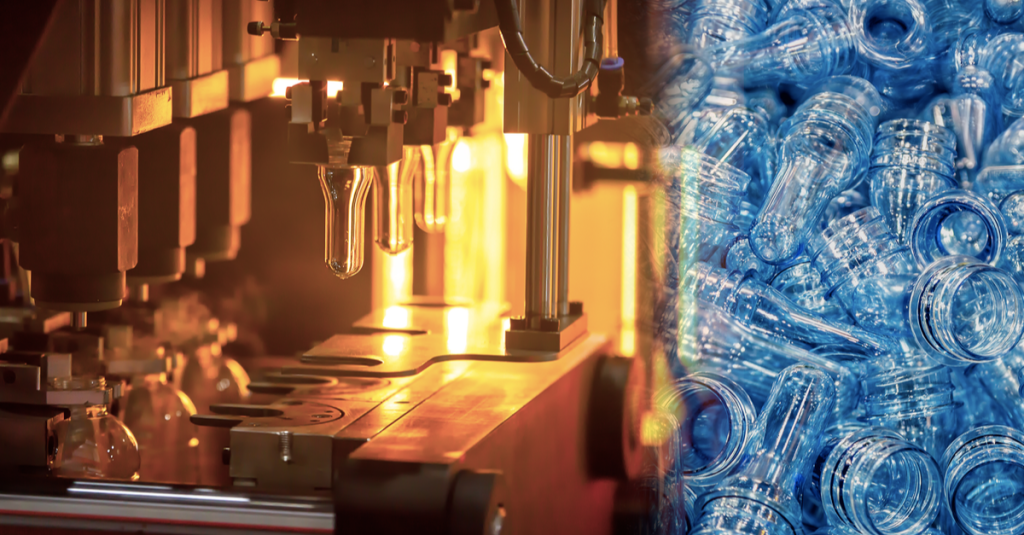

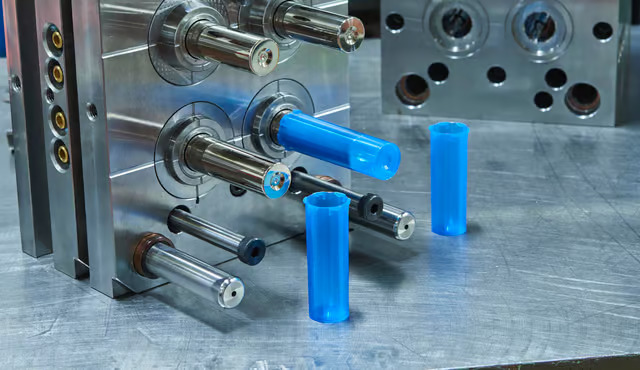

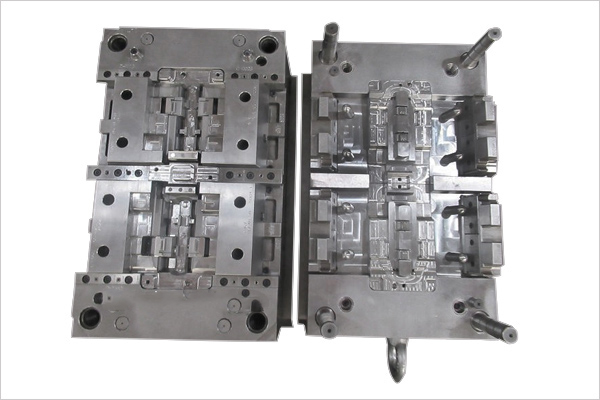

Injection molding is a versatile manufacturing process that plays a vital role in producing precise, durable, and cost-effective packaging solutions. By injecting molten plastic or other materials into custom-designed molds, this method creates high-quality products such as food containers, lids, caps, bottles, and trays. Known for its ability to ensure uniformity and excellent finishes, injection molding meets the demands of modern packaging with efficiency and reliability.

This process offers numerous advantages, including the production of lightweight yet sturdy packaging that reduces material usage without compromising strength or performance. By lowering production costs and minimizing waste, it supports sustainability efforts while maintaining product functionality. Injection molding also enables intricate designs and features, such as snap-fit closures, tamper-evident seals, and embossed logos, enhancing usability and brand visibility.

Advanced technologies, including multi-cavity molds and automation, further enhance efficiency and scalability, enabling the rapid production of large volumes with consistent quality and shorter lead times. The process is compatible with a wide range of materials, including biodegradable and recycled plastics, making it an excellent choice for environmentally conscious packaging solutions.