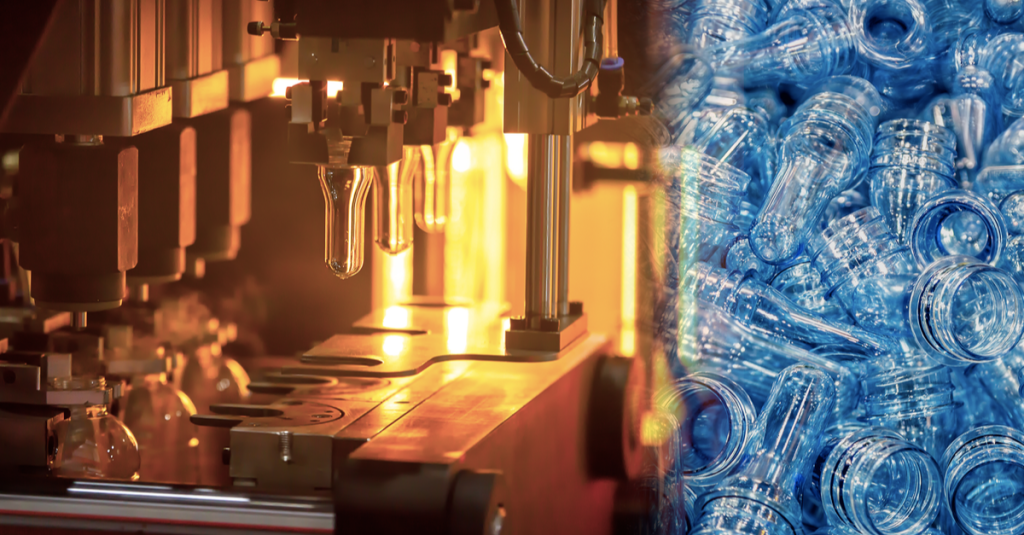

Injection molding is a popular method for prototyping due to its ability to produce high-quality parts that closely replicate the final product. By utilizing this technique, manufacturers can validate designs, test functionality, and identify potential issues early in the development process. Although traditionally associated with large-scale production, advancements in technology and materials have made injection molding increasingly accessible for prototyping applications.

Advantages of Injection Molding for Prototyping

High Precision and Accuracy

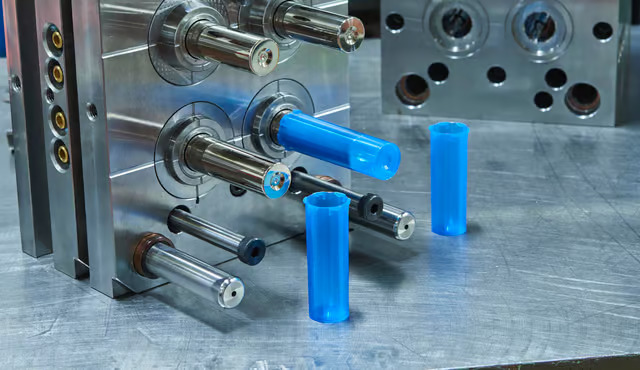

Injection molding produces prototypes with tight tolerances and detailed geometries. This allows for the creation of complex shapes, intricate details, and functional features that closely resemble production-grade components.Material Versatility

Prototypes can be made from the same materials intended for mass production, such as thermoplastics, thermosets, or elastomers. This enables manufacturers to evaluate material performance, including strength, flexibility, and chemical resistance, under real-world conditions.Surface Finish and Aesthetics

The process delivers excellent surface finishes, minimizing the need for post-processing. This is particularly beneficial for products requiring specific textures, polished surfaces, or clear components.Functionality Testing

Prototypes created through injection molding are functional, allowing for testing in actual operating environments. This includes mechanical, thermal, and chemical evaluations to ensure the design meets performance requirements.Scalability

Injection-molded prototypes can seamlessly transition to full-scale production, as the tooling and processes are already in place. This reduces the time and cost associated with redesigning molds or adapting manufacturing workflows.

Key Considerations for Prototyping with Injection Molding

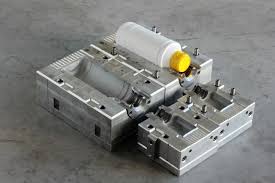

Tooling Cost and Time

Injection molding requires the fabrication of a mold, which can be expensive and time-consuming. For prototyping, manufacturers often use soft tooling made from aluminum or other cost-effective materials instead of hardened steel. Soft tooling is faster and cheaper to produce, although it has a limited lifespan compared to production-grade molds.Batch Size

Injection molding is most efficient for medium to large prototype batches. For low-volume production, alternative rapid prototyping methods, such as 3D printing or CNC machining, may be more economical.Design for Manufacturability (DFM)

Prototypes should be designed with the injection molding process in mind. This includes considerations for parting lines, draft angles, and wall thickness to ensure the mold can fill properly and produce defect-free parts.Cycle Time

While each cycle is relatively quick, the overall timeline for injection molding prototypes includes mold fabrication and setup. Proper planning and collaboration with experienced mold makers can streamline this process.