Closure manufacturing—such as the production of caps and lids for bottles and containers—uses two main plastic molding techniques: Injection Molding and Compression Molding. Each method has distinct characteristics, advantages, and use cases depending on the requirements of the final product.

1. Process Overview

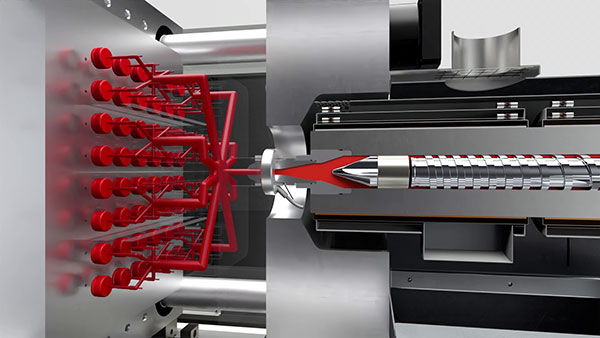

Injection Molding

Plastic resin is melted and injected under high pressure into a mold cavity.

The material cools and solidifies into the shape of the closure.

The mold then opens, and the part is ejected.

Compression Molding

Pre-measured plastic material (typically in pellet or preform form) is placed directly into an open mold.

The mold closes and compresses the material into the shape of the closure using heat and pressure.

The closure is cured (hardened), then ejected.

2. Material Usage

Injection Molding: Primarily uses thermoplastics (e.g., polypropylene).

Compression Molding: Commonly used for both thermosets and thermoplastics, especially high-density polyethylene (HDPE) in closures.

3. Cycle Time & Efficiency

Injection Molding: Shorter cycle times; ideal for high-speed, high-volume production.

Compression Molding: Slightly longer cycle times but can be more energy-efficient with less material waste.

4. Tooling and Equipment Costs

Injection Molding: Higher upfront tooling and machinery costs; suitable for long production runs.

Compression Molding: Lower initial tooling costs; preferred for medium-volume production or when frequent mold changes are needed.

5. Precision and Design Complexity

Injection Molding:

Allows for more intricate and detailed designs.

Supports closures with complex geometries, threads, tamper-evident bands, and undercuts.

Compression Molding:

Typically used for simpler designs.

Can produce closures with excellent dimensional stability but may be less suitable for intricate detailing.

6. Waste and Sustainability

Injection Molding: Generates more sprue and runner waste, though it can often be recycled.

Compression Molding: More material-efficient with little to no waste during molding.

7. Surface Finish and Product Consistency

Injection Molding:

Generally produces smoother surface finishes.

High consistency from part to part, making it ideal for branded consumer closures.

Compression Molding:

Good surface finish but can vary slightly.

Excellent for closures requiring strength and tight sealing properties.

8. Common Applications in Closures

Injection Molding:

Beverage bottle caps (especially carbonated drinks)

Tamper-evident closures

Flip-top and dispensing caps

Compression Molding:

Water and milk bottle caps

Simple threaded caps

Closures where cost and strength are key concerns