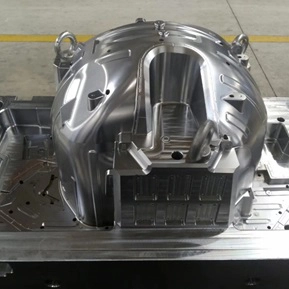

Automobile moulds are essential tooling used to produce a wide range of vehicle components — from interior and exterior plastic parts to metal die-cast structural elements. These moulds must meet extremely tight tolerances, high durability standards, and be capable of high-volume production for global automotive OEMs and Tier-1 suppliers. Business Research Insights

1. Global Leaders in Automotive Mould Manufacturing

Magna International

Magna International is one of the world’s largest suppliers of automotive parts and moulded components, including plastic injection moulds used for bumpers, interior trim and body panels. It supports numerous global OEMs through innovation in materials and mould design. hollyplasticparts.com

Simoldes Group

A leading European mould maker based in Portugal, Simoldes supplies high-precision plastic injection moulds to major automotive OEMs and suppliers such as Renault, Volvo, BMW and Mercedes-Benz. The company has a global footprint with multiple production units and service offices. Wikipedia

Chinese Precision Mould Makers

China is a major hub for automobile mould producers, particularly for plastic injection moulds. Well-known companies include:

Shenzhen New Century Tooling

Beijing Long Shan Brothers Mould

TECH PLASTIC MOLD

Suzhou Fce Precision Electronics

These firms are recognized for fast lead times, precision tooling and strong export activity to global automotive markets. Accio

Kaihua Moulds

A respected Chinese supplier of high-performance moulds, especially for complex automotive plastic parts such as door panels, airbag covers and structural interior components. Their use of advanced CNC machining and flow analysis ensures quality suitable for premium OEM specifications. KAIHUA

2. Regional and Specialized Mould Manufacturers

SSI Moulds (India)

SSI Moulds is among India’s prominent automotive mould manufacturers, providing injection moulds and plastic parts solutions to major domestic brands and exporting to overseas markets. SSI Moulds

Adith Plastic (India)

Based in Mumbai, Adith Plastic specializes in customized automobile plastic moulds and supplies a variety of automotive components — including lighting system moulds, trims and dashboard moulds — supporting India’s automotive OEMs and supply chain. Adith Plastic

Awanti Polymoulds (India)

Awanthi Poly Moulds produces high-precision plastic moulds for automotive and engineering applications, with advanced facilities capable of large production volumes. hollyplasticparts.com

Tan Tech Moulds (India)

An ISO-certified mould maker located near Chennai, Tan Tech offers automotive injection moulds (50–550 ton) and has a growing presence within the Indian automotive tooling landscape. Tan Tech Moulds

3. Die-Casting and Metal Mould Makers

While many manufacturers focus on plastic injection moulds, the automotive industry also relies heavily on die-casting moulds for metal components:

Nemak (Mexico): Known for aluminium engine blocks, transmission housings and structural components delivered in high volumes. PW Consulting

Gibbs Die Casting and Dynacast: Major players in both aluminium and zinc die-cast moulding, covering complex structural parts for global automakers. PW Consulting

4. What Defines a Leading Automobile Mould Manufacturer

Leading mould manufacturers typically share these characteristics:

✅ Advanced Technology & Precision Engineering

They use state-of-the-art CNC machining, CAE/CAD design tools, and sophisticated flow/thermal simulation to ensure moulds meet strict OEM standards.

✅ Global OEM Approvals and Certifications

Many top players have IATF and ISO quality certifications and supply directly to major vehicle manufacturers.

✅ High Production Capacity & Delivery Performance

Manufacturers are chosen for fast response times, reliable delivery schedules and the ability to scale production for mass-market vehicle programmes. Accio

✅ Comprehensive After-Sales Support

Support services such as mould maintenance, refurbishment, and technical troubleshooting extend the life and performance of tools.

5. Industry Trends Impacting Automobile Mould Manufacturers

🔹 Shift to Lightweight Materials & EV Components

New electric-vehicle designs demand innovative moulds for lightweight plastics and composite materials. GuangChao

🔹 Automation & Digital Integration

Manufacturers increasingly adopt automation and digital process controls to improve precision and reduce cycle times.

🔹 Regional Growth in Asia-Pacific

China and India are experiencing rapid growth in automotive mould demand due to expanding vehicle production and investment in local tooling capabilities. PW Consulting