Lightweighting in closure production refers to the process of reducing the amount of material used to manufacture bottle and container closures, without compromising their functionality, performance, or safety. This practice is increasingly adopted in the packaging industry to lower material costs, reduce environmental impact, and improve supply chain efficiency.

1. Importance of Lightweighting

Cost Reduction: Less material used per closure means significant cost savings in mass production.

Environmental Impact: Reduced material usage lowers carbon footprint and resource consumption.

Regulatory Compliance: Aligns with sustainability targets and Extended Producer Responsibility (EPR) mandates.

Transportation Efficiency: Lighter closures decrease overall package weight, leading to reduced fuel use during logistics.

2. Common Lightweighting Techniques

A. Material Optimization

Resin Selection: Use of high-performance polymers (e.g., HDPE, PP) with improved mechanical properties allows for thinner wall designs.

Additive Engineering: Integration of mineral fillers or foaming agents can reduce density while maintaining strength.

B. Structural Redesign

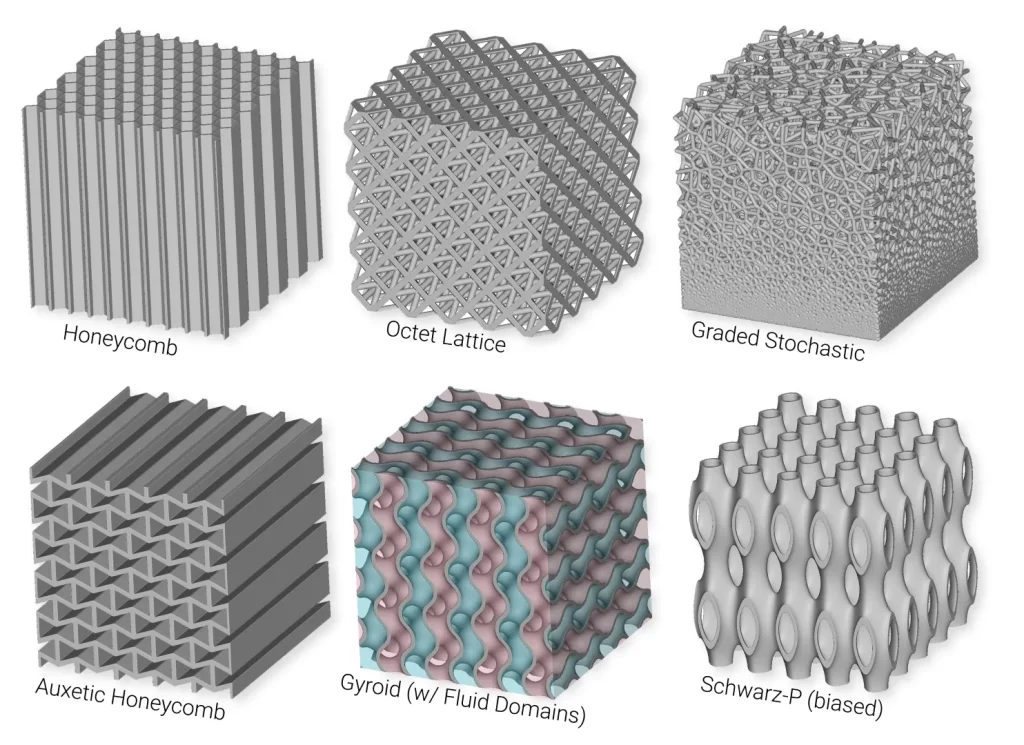

Geometry Modification: Optimizing ribbing, thread design, and wall thickness to maintain strength with less material.

Finite Element Analysis (FEA): Simulation tools used to predict stress points and identify areas where material can be safely reduced.

Snap-Fit Design: Transition from threaded to snap-fit closures in certain applications reduces material use and simplifies manufacturing.

C. Mold and Process Engineering

High-Cavitation Molds: Optimized molds reduce cycle times and material waste.

Precision Molding: Tight control of processing parameters ensures minimal material use while maintaining closure integrity.

Compression Molding: Offers better material distribution and weight consistency compared to injection molding for certain closure types.

D. Down-gauging

Wall Thickness Reduction: Controlled reduction in closure wall thickness based on stress analysis and product compatibility testing.

Thread Light-weighting: Reducing the number or depth of threads without impacting seal performance.

3. Case Examples

Carbonated Beverage Closures: Reduction of thread turns and cap height while maintaining pressure resistance.

Water Bottle Caps: Transition from 3-piece to 1-piece caps using advanced HDPE grades.

Flip-Top Closures: Redesigning hinges and living areas to use less plastic while maintaining function.

4. Challenges and Considerations

Seal Integrity: Must ensure no compromise on product safety and shelf life.

Consumer Usability: Caps must remain easy to open/close.

Compatibility: Must be compatible with existing bottling lines and capping equipment.

Material Stress and Creep: Thinner structures may be more susceptible to deformation over time.

5. Future Trends

Bio-based Materials: Incorporating plant-derived plastics in lightweight designs.

AI-Driven Design Optimization: Using machine learning to predict optimal design configurations.

Circular Economy Integration: Designing lightweight closures that are also easier to recycle.

Conclusion

Lightweighting techniques in closure production represent a critical innovation area in sustainable packaging. Through smart material choices, design optimization, and advanced molding technologies, manufacturers can reduce costs and environmental impact while maintaining product performance. As sustainability pressures increase, lightweighting will continue to play a central role in closure innovation.