1. Introduction

A mold base is the foundation of a mold used in injection molding, die casting, and other forming processes. It provides the structural support and alignment for the mold components, such as the core, cavity, ejector system, and cooling circuits. Selecting the appropriate mold base materials and adhering to industry standards are critical to ensuring mold performance, durability, and cost-efficiency.

2. Mold Base Materials

Mold bases are typically made from a variety of tool steels and other metals based on the application, production volume, and molding materials. Below are common mold base materials and their characteristics:

2.1 P20 Steel

Type: Pre-hardened tool steel

Hardness: ~28-32 HRC

Features:

Good machinability

Uniform hardness

Suitable for moderate production volumes

Applications: General-purpose molds, plastic injection molds

2.2 H13 Steel

Type: Hot-work tool steel

Hardness: Can be heat treated up to 48-52 HRC

Features:

High heat resistance

Excellent toughness

Good for high-volume production

Applications: Die casting molds, high-temperature applications

2.3 S50C / 1050 Carbon Steel

Type: Medium carbon steel

Hardness: Can be hardened up to 50 HRC

Features:

Economical

Good strength and machinability

Applications: Base plates, low-cost mold bases

2.4 Stainless Steels (e.g., 420, 440C)

Type: Corrosion-resistant tool steels

Hardness: High, depending on grade

Features:

Corrosion resistance

High polishability

Applications: Medical molds, optical lenses, cleanroom environments

2.5 Aluminum (e.g., QC-10, Alumold)

Type: High-strength aluminum alloys

Features:

Lightweight

Good thermal conductivity

Easy to machine

Limitations: Lower wear resistance

Applications: Prototype molds, low-volume production

3. Mold Base Standards

Several global standards define the design, dimensions, and interchangeability of mold bases and components. These standards ensure compatibility and ease of replacement across different systems and suppliers.

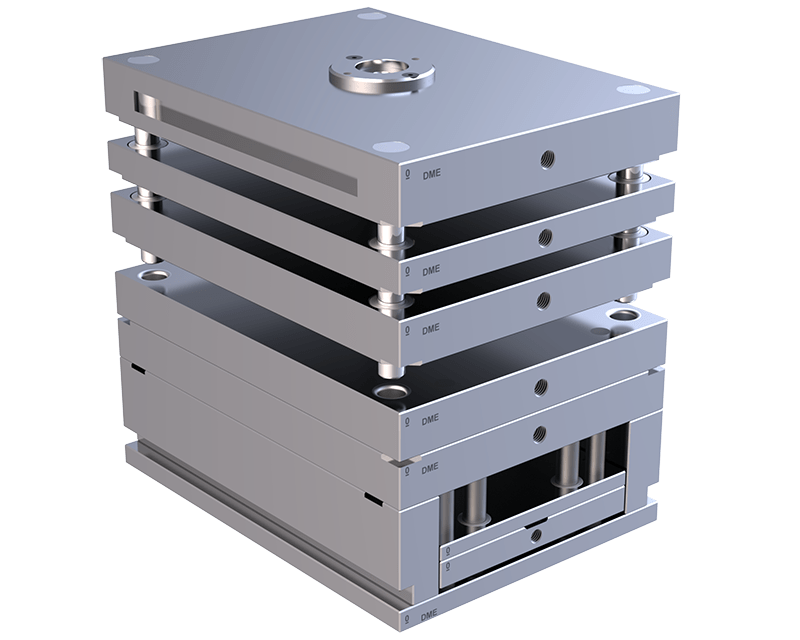

3.1 DME (Detroit Mold Engineering) Standard

Originated in the USA

Commonly used in North America and internationally

Offers standard mold base sizes, guide pins, bushings, and ejector systems

3.2 HASCO Standard

German-based standard

Popular in Europe and widely adopted worldwide

Known for precise dimensions and quality

Offers metric-based mold bases and components

3.3 MISUMI

Japanese standard, used widely in Asia

Provides customizable mold base components with tight tolerances

Offers both JIS and ISO-compatible options

3.4 JIS (Japanese Industrial Standard)

Standard for mold components and materials in Japan

Ensures compatibility with Japanese tooling practices

3.5 ISO (International Organization for Standardization)

Global standard covering materials, tolerances, and terminology

Increasingly adopted to unify global tooling practices

4. Factors in Selecting Mold Base Materials and Standards

When choosing mold base materials and standards, consider:

Production volume: High volumes need harder, wear-resistant materials

Material being molded: Abrasive or corrosive plastics require specialized steels

Budget constraints: Balance between performance and cost

Precision requirements: Tighter tolerances may dictate higher-grade materials and standards

Availability: Regional availability of standards and materials affects cost and lead time

5. Conclusion

The selection of the right mold base material and adherence to appropriate standards is essential for mold performance, lifespan, and efficiency. Understanding the properties of different materials and global standards like DME, HASCO, and JIS helps manufacturers make informed decisions that balance quality, cost, and production needs.