Polishing and texturing are critical processes in the manufacturing of houseware mould dies. These steps not only influence the aesthetic appeal of the final product but also play a vital role in its functionality, durability, and ease of release from the mould. Below is a comprehensive overview of these processes in the context of houseware moulds.

1. Importance of Polishing and Texturing

Polishing and texturing serve distinct yet complementary purposes in mould die preparation:

Polishing ensures a smooth surface finish, reduces friction during part ejection, and prevents product defects.

Texturing adds patterns or surface finishes for aesthetic enhancement, improved grip, or branding purposes.

Together, they help achieve high-quality end products in items like plastic containers, utensils, kitchen tools, and other consumer houseware goods.

2. Polishing of Houseware Mould Dies

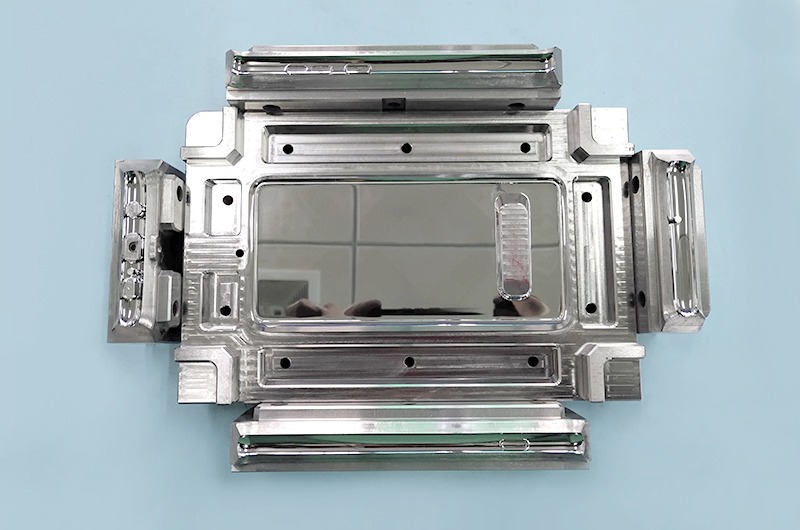

Polishing involves refining the surface of the mould cavity to reduce surface roughness.

Objectives of Polishing:

Achieve mirror-like finishes for transparent or glossy plastic products.

Improve part release and reduce wear and tear on the mould.

Eliminate minor tool marks, EDM (electrical discharge machining) traces, or machining defects.

Common Polishing Methods:

Manual Polishing: Using abrasives like diamond paste, polishing stones, or cloth wheels.

Mechanical Polishing: Using rotary tools or polishing machines for uniform surface finishes.

Electropolishing: An electrochemical process that smooths and brightens metal surfaces.

Ultrasonic Polishing: Used for intricate and delicate parts.

Polishing Grades:

Polishing levels range from coarse to ultra-fine, depending on the product requirements. For houseware:

Transparent items (like food storage containers) may need SPI A1 (mirror finish).

Opaque items may only require a matte or satin finish (SPI B or C grades).

3. Texturing of Houseware Mould Dies

Texturing refers to the process of creating deliberate surface patterns on the mould cavity.

Objectives of Texturing:

Enhance the product’s appearance (e.g., leather-like, wood-grain, geometric patterns).

Mask surface imperfections.

Improve grip or tactile feel of the product.

Reduce visibility of weld lines or flow marks.

Common Texturing Techniques:

Chemical Etching: A controlled chemical process used to etch patterns into the mould surface. Widely used in decorative texturing.

Laser Texturing: Offers high precision and consistency, useful for complex or micro patterns.

Sandblasting/Bead Blasting: Produces a matte or satin finish by impacting the surface with abrasive materials.

Photochemical Etching: Used for detailed and consistent textures across the mould surface.

Texture Standards:

VDI (Verein Deutscher Ingenieure) Standards: Commonly used for texture classification.

Texture levels range from fine to coarse (e.g., VDI 12 to VDI 45), depending on product requirements.

4. Considerations in Polishing and Texturing

Material of the Mould: Hardened tool steels require different approaches than softer materials.

Design Geometry: Complex cavities and undercuts may need specialized tools or manual intervention.

Product Type: Polishing and texturing must align with the product’s end-use — whether functional, aesthetic, or both.

Maintenance Needs: Highly polished moulds may require more frequent maintenance.

5. Challenges and Best Practices

Challenges:

Achieving uniform texture in deep cavities.

Avoiding distortion or dimensional changes during polishing.

Maintaining texture integrity over time.

Best Practices:

Use skilled technicians with experience in mould finishing.

Follow standard operating procedures for polishing and texturing.

Conduct sample testing before full-scale texturing.

Ensure proper mould maintenance to preserve polish and texture quality.

Conclusion

Polishing and texturing are vital to producing high-quality, durable, and visually appealing houseware products. By combining skilled craftsmanship with advanced techniques, manufacturers can enhance the performance, appearance, and marketability of their products. A well-polished and textured mould die ultimately translates to fewer defects, longer mould life, and superior consumer satisfaction.