In the competitive world of cosmetics, speed, customization, and innovation are crucial. Whether it’s for packaging design, applicators, or limited-edition product formats, the development of cosmetic moulds is a key stage in bringing new products to market. Traditional mould-making processes can be time-consuming and expensive. Enter 3D printing—a transformative technology that is revolutionizing the way cosmetic moulds are prototyped.

Why Prototype Cosmetic Moulds?

Prototyping allows manufacturers to:

Visualize the final product before mass production

Test form, fit, and functionality

Evaluate aesthetics and ergonomics

Identify design flaws early

Reduce costly design iterations in metal tooling

Benefits of 3D Printing for Cosmetic Mould Prototyping

Speed and Agility

3D printing dramatically shortens lead times from weeks to days or even hours.

Enables rapid iteration, especially useful during product development sprints.

Cost-Effective Iteration

Eliminates the need for CNC-machined or cast prototypes in early stages.

Reduces waste and tooling costs.

High Level of Customization

Easily create unique mould designs for boutique and personalized cosmetic lines.

Complex geometries that are difficult with traditional methods are easily achievable.

Material Versatility

A wide variety of 3D printable materials simulate production-grade plastics or even rubber-like materials.

Transparent and semi-rigid resins can replicate the look and feel of actual packaging components.

Sustainability

Digital design and additive manufacturing reduce material waste.

Eco-friendly materials are increasingly available for prototyping.

Applications in the Cosmetic Industry

Packaging Moulds: Caps, bottles, jars, and compact cases.

Applicators: Lipstick bullets, mascara brushes, droppers, and roller balls.

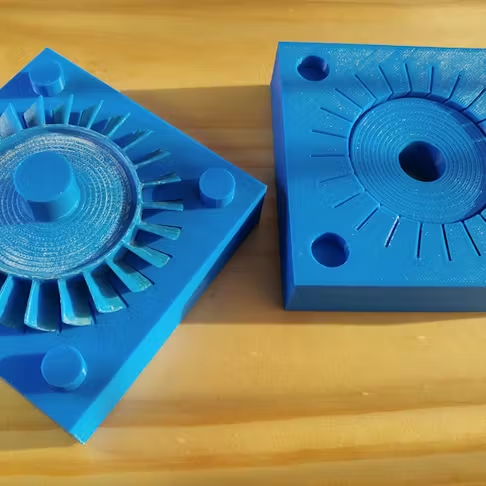

Tooling Inserts: Pilot tools or cavity inserts for short-run injection moulding.

Display and Marketing Models: Concept models for promotional events and customer feedback.

Popular 3D Printing Technologies Used

SLA (Stereolithography): Offers high-resolution prints ideal for detailed cosmetic components.

FDM (Fused Deposition Modeling): Suitable for basic geometric moulds and fast, low-cost prototyping.

PolyJet: Allows multi-material printing, great for simulating overmolds or multi-component designs.

SLS (Selective Laser Sintering): Useful for functional testing due to its durability and heat resistance.

Case Example

A leading skincare brand used SLA 3D printing to prototype a new lotion pump. Within three days, they iterated through five designs, adjusting nozzle size and user ergonomics. The final model was tested for functionality and customer appeal, saving weeks of development and thousands in tooling costs.

Challenges and Considerations

3D printed moulds are not always suitable for high-pressure injection moulding.

Surface finish may require post-processing for aesthetic products.

Material behavior under actual production conditions should still be validated with final mould materials.

Conclusion

3D printing has become an indispensable tool in cosmetic mould prototyping. It enables rapid, cost-effective, and innovative product development, empowering brands to stay ahead in a fast-moving market. As materials and printer technologies continue to evolve, the boundary between prototype and production-ready tooling is rapidly shrinking—making 3D printing an essential element of future-ready cosmetic manufacturing.