1. Rising Demand Across End-Use Industries

Construction: PVC’s strength, flame retardancy, and cost-effectiveness make it ideal for fittings, pipes, and window profiles.

Medical: Growth in healthcare has spurred demand for medical-grade PVC components like tubing and connectors.

Automotive: Lightweight PVC parts contribute to improved fuel efficiency and reduced emissions in vehicles.

Consumer Goods: Flexible and rigid PVC products are being used in everything from toys to electronics casings.

2. Sustainability and Recycling Focus

The industry is shifting toward sustainable practices, such as:

Post-consumer recycled (PCR) PVC in molding applications.

Development of green additives and non-phthalate plasticizers.

Companies are investing in closed-loop recycling systems for PVC waste and scrap.

3. Technological Advancements

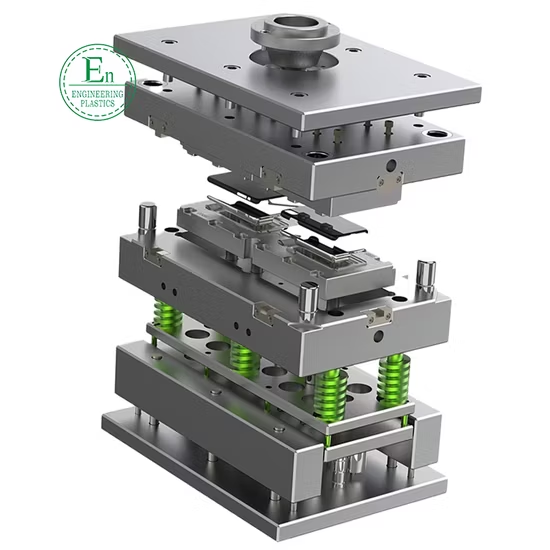

Improved mold design: Enhances efficiency and reduces cycle times.

Precision molding equipment: Enables more complex, high-tolerance PVC parts.

AI and IoT in production lines for real-time monitoring and predictive maintenance.

Use of hybrid and electric injection molding machines for energy efficiency.

4. Shift to Lead-Free and Low-VOC Formulations

Due to tighter global regulations (e.g., REACH, RoHS), there’s a movement toward:

Lead-free stabilizers replacing traditional heavy metal-based ones.

Low-VOC (Volatile Organic Compound) compounds to meet air quality and safety standards.

5. Regional Growth Patterns

Asia-Pacific continues to dominate the market, driven by infrastructure and manufacturing growth in China and India.

North America and Europe are focusing on innovation and regulatory compliance.

Latin America and Africa are emerging markets with infrastructure-led demand growth.

6. Customization and Small-Batch Production

Shorter product lifecycles in consumer goods and medical fields are driving the need for:

Rapid prototyping using PVC-compatible tools.

Flexible, low-volume production runs.

7. Supply Chain and Resin Pricing Volatility

Global PVC resin markets are affected by:

Raw material availability (e.g., ethylene and chlorine).

Geopolitical tensions and transportation disruptions.

Fluctuations in energy prices, especially impacting chlor-alkali production.